In the quest to enhance the efficiency of centrifugal compressors, a critical component in the energy sector, researchers have made significant strides. A recent study published in the journal *Mechanical Sciences* (translated as *机械科学*) delves into the intricate dynamics of these machines, offering insights that could revolutionize their design and performance.

At the heart of this research is J. Chen, a leading figure from the Zhejiang Key Laboratory of Multiflow and Fluid Machinery at Zhejiang Sci-Tech University in Hangzhou, China. Chen and his team have been investigating the impact of the gap between the diffuser blade and the impeller blade on the internal flow and aerodynamic performance of centrifugal compressors. This gap, defined by the ratio \( R_d = R_2 / R_1 \), where \( R_2 \) is the diffuser inlet radius and \( R_1 \) is the impeller outlet radius, plays a pivotal role in the efficiency and operational dynamics of these machines.

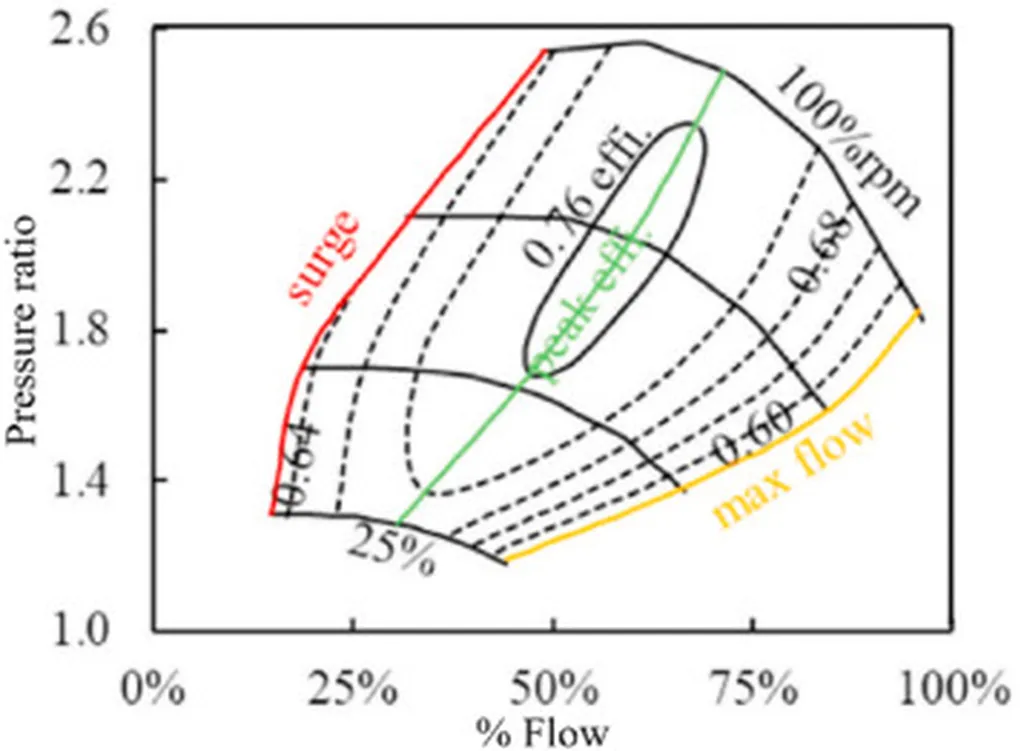

The study employs advanced numerical simulations to explore how variations in \( R_d \) affect key performance metrics such as efficiency, differential pressure, and the minimum allowable mass flow rate. “By understanding the complex flow dynamics within the compressor, we can identify areas where energy loss occurs and develop strategies to minimize it,” Chen explains. This understanding is crucial for enhancing the overall efficiency of centrifugal compressors, which are widely used in various industries, including energy production and manufacturing.

One of the key findings of the study is the significant improvement in intake conditions at the diffuser inlet as \( R_d \) increases. This improvement is attributed to the reduction in energy loss from airflow impacting the diffuser blades. The research also captures the spatiotemporal evolution of the internal flow under unsteady operational states, providing a comprehensive view of the pressure and velocity fluctuations within the compressor. Fast Fourier transform (FFT) spectral analysis was employed to deeply analyze these fluctuations, revealing the intricate interplay between pressure and velocity.

The implications of this research are far-reaching for the energy sector. Centrifugal compressors are integral to many energy systems, and improving their efficiency can lead to substantial energy savings and reduced operational costs. “Our findings offer physical insights into enhancing the efficiency and lowest allowable mass flow rate of centrifugal compressors,” Chen notes. This could pave the way for more efficient and cost-effective energy solutions, benefiting both industrial applications and environmental sustainability.

As the energy sector continues to evolve, the insights gained from this research could shape the future of centrifugal compressor design. By minimizing energy loss and optimizing performance, engineers can develop more advanced and efficient machines that meet the growing demands of the energy industry. The study published in *Mechanical Sciences* serves as a testament to the ongoing innovation in this field, highlighting the importance of understanding the fundamental principles that govern the performance of these critical components.

In the words of Chen, “This research not only advances our understanding of centrifugal compressors but also opens up new avenues for improving their design and performance.” As the energy sector continues to push the boundaries of efficiency and sustainability, such advancements are crucial for meeting the challenges of the future.