In the quest for sustainable materials, researchers have long grappled with the challenge of balancing performance and cost, particularly in the realm of biopolymers. A recent study published in *Materials Research* (or *Pesquisa em Materiais* in English) offers a promising solution, leveraging artificial intelligence to revolutionize the production and quality control of these eco-friendly materials. The research, led by Audelis de Oliveira Marcelo Júnior, introduces a groundbreaking framework that could reshape the landscape of composite material modeling and, by extension, the energy sector.

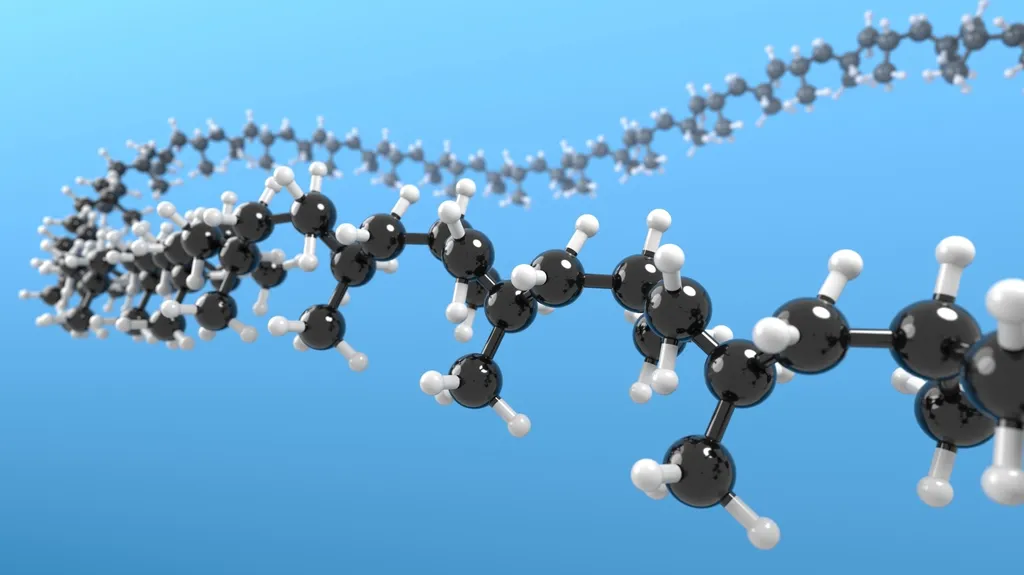

At the heart of this innovation lies the aiMat framework, a sophisticated integration of Computer Vision and the Extended Finite Element Method (XFEM). The framework addresses a critical bottleneck in the production of high-performance biopolymers: the dependence of mechanical properties on fiber arrangement within the matrix. Traditionally, ensuring the quality of these materials has been a costly and time-consuming process. However, aiMat offers a more efficient and accessible workflow by creating virtual representations of the material’s microstructure from simple images.

“This virtualization allows us to generate numerical models with unprecedented efficiency,” explains Audelis de Oliveira Marcelo Júnior. “By using Computer Vision to analyze images of the material’s microstructure, we can create detailed virtual models that serve as the basis for FEM and XFEM simulations. This not only reduces the need for extensive physical testing but also accelerates the development process.”

The implications of this research are far-reaching, particularly for the energy sector. Biopolymers are increasingly being used in applications ranging from wind turbine blades to insulating materials for buildings. The ability to model and predict the mechanical properties of these materials with greater accuracy and speed can lead to significant cost savings and improved performance.

Moreover, the aiMat framework has the potential to democratize access to advanced modeling techniques. “By making the process more efficient and less resource-intensive, we can enable smaller companies and research institutions to participate in the development of high-performance biopolymers,” says Marcelo Júnior. This could foster innovation and accelerate the adoption of sustainable materials across various industries.

The integration of Artificial Intelligence and advanced computational methods represents a significant step forward in the field of materials science. As the energy sector continues to seek sustainable and high-performance solutions, the aiMat framework offers a compelling tool for overcoming the challenges of quality control and material development. With its publication in *Materials Research*, this research not only contributes to academic knowledge but also paves the way for practical applications that could shape the future of the energy industry.

As the world moves towards a more sustainable future, the role of innovative technologies like aiMat will be crucial. By harnessing the power of AI and advanced modeling techniques, researchers and industry professionals can work together to develop materials that are not only environmentally friendly but also highly efficient and cost-effective. The journey towards sustainability is complex, but with tools like aiMat, the path becomes clearer and more achievable.