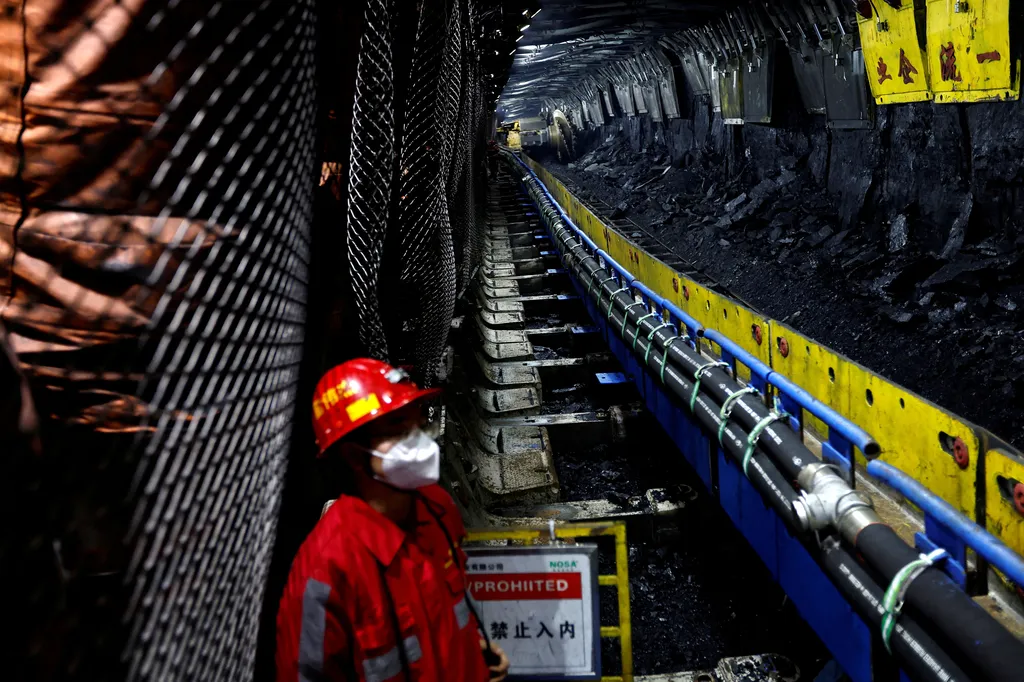

In the heart of China’s coal country, a breakthrough in fault detection technology is poised to revolutionize the energy sector. J. Shi, a researcher from the Second Coal Mine of Cuncaota, CHN Energy Shendong Coal Group Co., Ltd, has led a team that has developed a novel method for diagnosing rub-impact faults in rotating machinery, a critical component in many energy production systems. The research, published in the journal *Mechanical Sciences* (which translates to *机械科学* in Chinese), promises to enhance the efficiency and safety of energy infrastructure.

Rub-impact faults are high-frequency issues that can significantly impact the performance and longevity of rotating machinery. Early detection of these faults has been a challenge due to low vibration properties and strong environmental noise. Shi’s team has addressed this challenge by developing a four-phase method that combines empirical mode decomposition (EMD) and dynamic convolutional neural networks (CNN).

“The key innovation here is the dynamic learning approach,” Shi explains. “By identifying the fault dynamics of the selected components, we can detect small faults in their initial stages, something that traditional methods struggle with.”

The method begins by decomposing the original vibration signals using EMD and selecting the most correlated components using the Pearson correlation coefficient (PCC). The team then identifies the fault dynamics of these components through dynamic learning, making them more sensitive to early-stage faults. A new fault feature deep fusion module is constructed based on the identified dynamics information and integrated into the convolutional neural networks to derive the diagnosis model, known as dynamic CNN. Finally, a misjudgment self-correction mechanism is implemented based on the comparison of fault dynamics in the verification phase.

The implications for the energy sector are substantial. Rotating machinery is ubiquitous in energy production, from turbines in power plants to drills in mining operations. Early detection of rub-impact faults can prevent costly breakdowns and improve the overall efficiency of these systems.

“Our method can detect rub-impact faults more effectively compared to traditional methods,” Shi states. “This can lead to significant cost savings and improved safety in energy production.”

The research not only offers a practical solution to a longstanding problem but also opens up new avenues for future developments. The integration of dynamic learning with deep learning models like CNN could inspire further innovations in fault detection and diagnosis across various industries.

As the energy sector continues to evolve, the need for advanced diagnostic tools becomes ever more critical. Shi’s research represents a significant step forward in this field, offering a glimpse into a future where machinery faults are detected and addressed before they can cause substantial damage. With the publication of this work in *Mechanical Sciences*, the stage is set for wider adoption and further refinement of this groundbreaking technology.