In the rapidly evolving world of additive manufacturing, a groundbreaking study led by Yunfei Li from the School of Materials Science and Engineering at North University of China has unveiled a novel approach to enhancing the mechanical performance of high-entropy alloys (HEAs) using laser powder bed fusion. This research, published in the esteemed journal *Materials & Design* (translated as *Materials and Design*), could significantly impact the energy sector by improving the strength and ductility of critical components.

The study focuses on the crystallization behaviors of CoCrFeMnNi HEAs, which are known for their exceptional mechanical properties and high-temperature stability. During the laser powder bed fusion process, these alloys often develop anisotropic microstructures with coarse columnar grains, which can compromise their service performance. Li and his team discovered that adjusting the construction angle could effectively regulate the mechanical performance of these alloys.

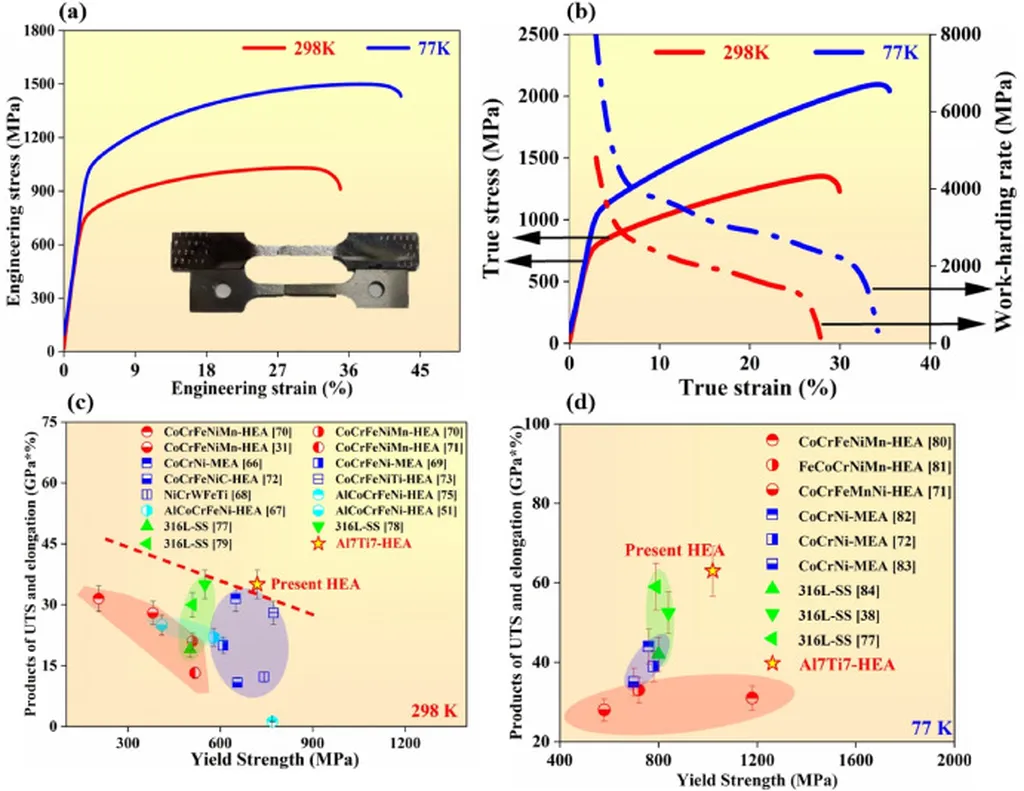

By comparing the regular construction form (0°/90°) with a 45° angle, the researchers found that the HEAs constructed at 45° exhibited a remarkable 24% increase in tensile strength while maintaining a high elongation rate of 31%. This improvement is attributed to the evolution of the molten pool under different construction angles. “We found that integrating construction angle regulation could promote equiaxed grains formation and interrupt the epitaxial growth of columnar grains,” Li explained. “This is achieved by decreasing the heat dissipation rate and enlarging the horizontal-section proportion of the molten pool in the working planes.”

The study also revealed that merely adopting the widely-known interlayer rotation strategy still results in coarse columnar grains growth in solid-solution HEAs. However, the combination of construction angle regulation and interlayer rotation leads to a more refined microstructure, enhancing the strengthening mechanisms (grain-boundary and dislocation strengthening) and improving fracture behaviors (microcrack/pore propagation).

The implications of this research are profound for the energy sector, where high-performance alloys are crucial for applications such as turbine blades, nuclear reactors, and other high-stress, high-temperature components. By optimizing the construction angle during the laser powder bed fusion process, manufacturers can produce components with superior mechanical properties, leading to enhanced efficiency and longevity.

“This research opens up new possibilities for the design and manufacturing of high-performance alloys,” Li said. “It provides a practical strategy for achieving the trade-off between strength and ductility, which is a long-standing challenge in materials science.”

As the energy sector continues to demand more robust and reliable materials, the findings from this study could pave the way for innovative solutions that meet these evolving needs. By leveraging the insights gained from this research, engineers and scientists can push the boundaries of additive manufacturing, unlocking new potential for high-entropy alloys and other advanced materials.