In the quest to enhance the reliability and efficiency of electric motors, a groundbreaking study led by J. Wodecki from the Faculty of Geoengineering, Mining and Geology at Wrocław University of Science and Technology in Poland, is shedding new light on the complexities of vibration analysis. Published in ‘Mechanical Sciences’ (Mechanika Teoretyczna i Stosowana), the research delves into the intricacies of cyclostationary analysis, a powerful method for detecting faults in rolling element bearings (REBs) within electric motors.

Electric motors are the workhorses of the energy sector, powering everything from industrial machinery to renewable energy systems. However, their efficiency and longevity are often hampered by bearing failures, which account for a significant portion of motor breakdowns. Traditional methods of vibration analysis have proven effective in identifying these faults, but the presence of additional cyclic components in electric motors has made the process far more challenging.

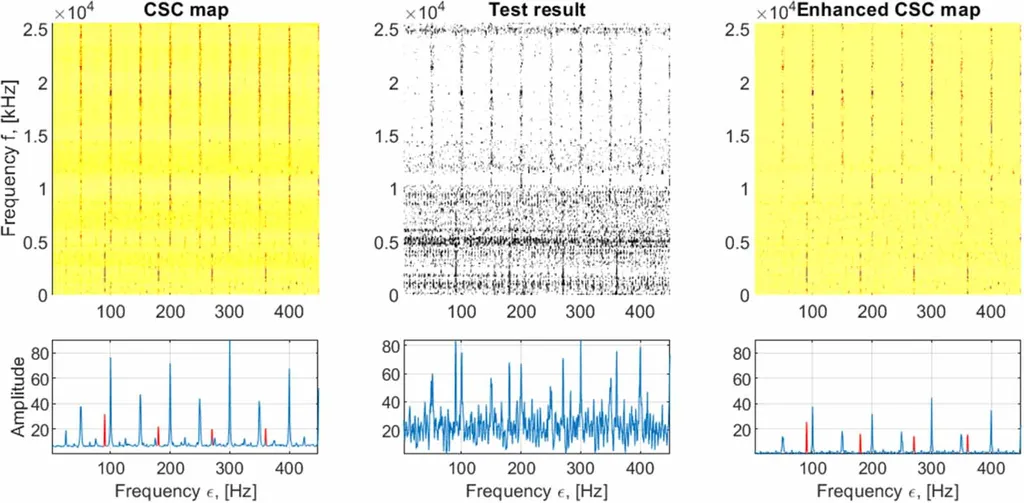

“Analyzing vibration signals measured on bearings in electric motors is much more challenging due to the presence of additional cyclic components on the bi-frequency map,” explains Wodecki. These components can stem from various mechanical sources, such as shaft misalignment, or electrical origins, including frequencies related to the power source. The complexity of these maps necessitates a deeper understanding and the development of new methods for automatic identification and interpretation of sources.

The study presents various cases that highlight the complexity of the bi-frequency map, emphasizing the need for advanced techniques to process these maps and develop novel indicators to assess the significance of features that describe faults. “We believe that this paper brings some new knowledge to the context of using cyclic spectral coherence (CSC) for bearing diagnosis in electric motors,” Wodecki states.

The implications of this research are profound for the energy sector. By improving the accuracy and efficiency of fault detection in electric motors, industries can reduce downtime, minimize maintenance costs, and enhance the overall performance of their equipment. The development of new methods for processing CSC maps and interpreting bi-frequency maps could revolutionize the way engineers approach bearing diagnostics, leading to more reliable and efficient electric motors.

As the energy sector continues to evolve, the need for advanced diagnostic tools becomes increasingly critical. This research not only addresses current challenges but also paves the way for future developments in the field. By deepening our understanding of cyclostationary analysis and its applications, we can unlock new possibilities for improving the reliability and efficiency of electric motors, ultimately driving progress in the energy sector.