In the quest to enhance the performance of materials used in high-temperature environments, such as those found in the energy sector, researchers have been exploring the effects of carbon additions to Ti48Al2Cr2Nb alloys. A recent study led by Feng Huang from the State Key Laboratory of Light Superalloys at Wuhan University of Technology and Hubei Longzhong Laboratory has shed new light on how carbon can influence the microstructure and mechanical properties of these alloys, potentially opening doors to more robust and efficient energy solutions.

The study, published in the journal *Materials Research Express* (translated to English as “Materials Research Express”), investigated Ti48Al2Cr2Nb alloys with varying carbon contents, ranging from 0 to 2.0 weight percent. The researchers found that carbon initially dissolves into the α₂-Ti₃Al and γ-TiAl matrices, causing lattice distortion. However, when the carbon content exceeds approximately 0.4 weight percent, Ti₂AlC precipitates begin to form.

“This precipitation is a game-changer,” said Huang. “It significantly alters the microstructure and mechanical properties of the alloy.”

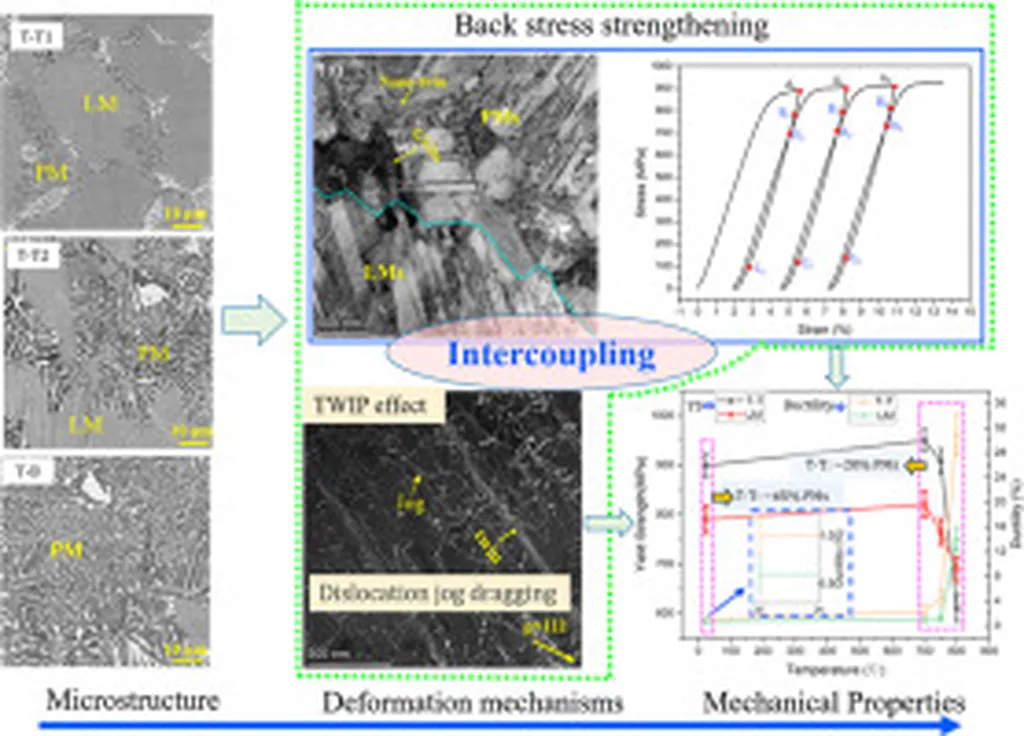

The study revealed that as the carbon content increases, the average α₂/γ lamellar colony size and the average Ti₂AlC aspect ratio decrease. Conversely, the volume fraction of Ti₂AlC and its average grain size increase. These changes contribute to a complex interplay of strengthening mechanisms, including solid-solution strengthening by carbon, grain refinement strengthening, and precipitation strengthening via Ti₂AlC.

The alloy with 0.8 weight percent carbon, designated Ti48Al2Cr2Nb-0.8C, demonstrated the best overall performance. It achieved the highest hardness (452.4 HV), elevated tensile strength (342 MPa), and compressive strength (2091.8 MPa) at room temperature. Additionally, it showed improved compressive strength at 800 °C (927 MPa), indicating its potential for high-temperature applications.

The implications for the energy sector are substantial. High-temperature environments, such as those in gas turbines and aerospace engines, demand materials that can withstand extreme conditions while maintaining their structural integrity. The enhanced mechanical properties observed in the Ti48Al2Cr2Nb-0.8C alloy suggest that it could be a promising candidate for these applications.

“Our findings could pave the way for developing more efficient and durable materials for energy generation and aerospace technologies,” Huang explained. “This research not only advances our understanding of TiAl-based composites but also highlights the importance of carbon additions in tailoring their properties.”

As the energy sector continues to evolve, the demand for materials that can perform reliably under extreme conditions will only grow. The insights gained from this study could shape future developments in the field, driving innovation and improving the performance of critical components in high-temperature applications. With the publication of this research in *Materials Research Express*, the scientific community now has a valuable resource to guide further exploration and application of TiAl-based composites in the energy sector.