In a significant stride towards advancing tissue engineering, researchers have developed a novel method to enhance the properties of chitosan foams, making them more suitable for medical applications. The study, led by M Polat from the Department of Chemical Engineering at Izmir Institute of Technology in Türkiye, presents a simple yet effective emulsion-templating approach to fabricate pristine chitosan foams with optimized strength and porosity. This breakthrough could have profound implications for the energy sector, particularly in the development of advanced bio-foams for various applications.

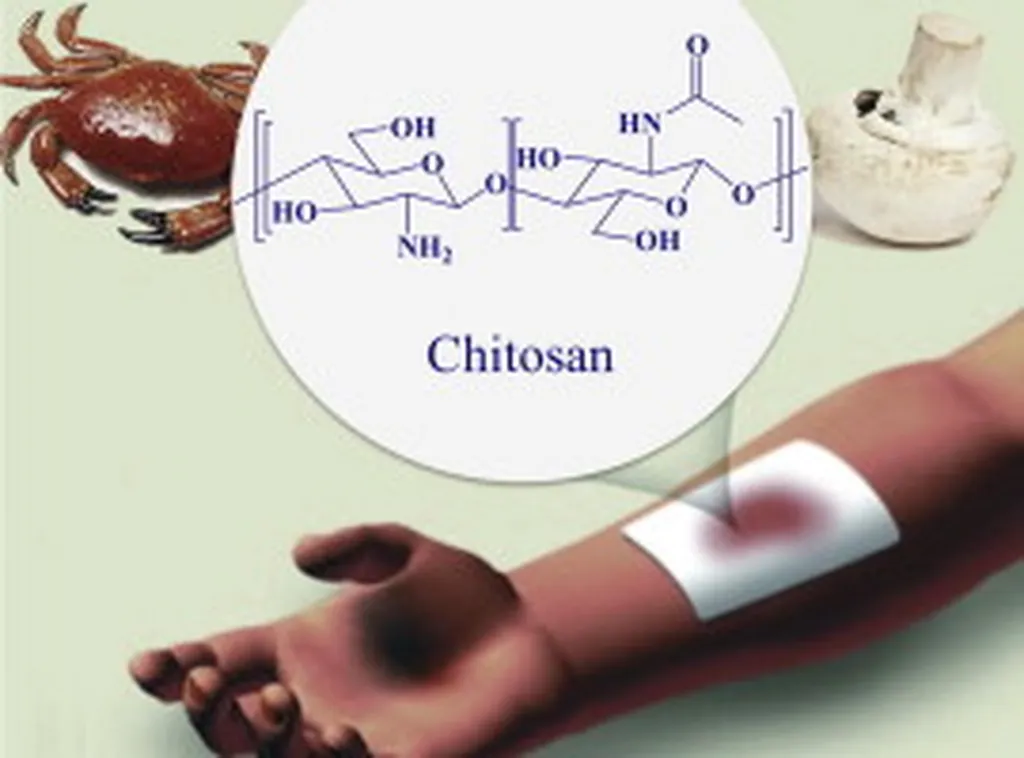

Chitosan, a biopolymer derived from chitin, is renowned for its excellent biocompatibility, biodegradability, and antimicrobial activity. However, pristine chitosan foams often fall short in terms of mechanical strength and porosity, limiting their use in hard-tissue engineering. The research team addressed this challenge by employing sodium dodecyl sulfate (SDS), a widely used biocompatible anionic surfactant, at trace levels to aid polymerization.

The resulting foams exhibit a dual-scale pore morphology, featuring cavities of 150–300 μm separated by around 50 μm thick chitosan walls containing large interconnecting openings. These walls are further populated with meso- and macropores of 50–500 nm. This intricate architecture is designed to support cell attachment and growth, facilitate proliferation, and enhance nutrient transport and metabolic exchange.

“Our approach not only improves the mechanical properties of chitosan foams but also enhances their porosity and surface area,” said Polat. “This makes them highly suitable for tissue engineering applications, where both strength and porosity are crucial.”

The foams demonstrated high surface area (up to 10 m²/g) and impressive mechanical strength, with a compressive resistance of 255 kPa at 40% strain for foams polymerized with 4% chitosan. Additionally, a preliminary drug-release study using vancomycin confirmed excellent loading and sustained release capabilities.

The implications of this research extend beyond tissue engineering. In the energy sector, advanced bio-foams with enhanced mechanical strength and porosity could find applications in areas such as insulation, filtration, and energy storage. The ability to tailor the pore structure and mechanical properties of these foams could lead to more efficient and sustainable energy solutions.

“This research opens up new possibilities for the use of chitosan foams in various industries,” said Polat. “The enhanced properties make them a promising material for future developments in both medical and energy sectors.”

The study, published in Materials Research Express (translated to English as “Materials Research Express”), represents a significant step forward in the field of bio-foams. As researchers continue to explore the potential of these materials, the findings could pave the way for innovative applications that leverage the unique properties of chitosan.