In a groundbreaking development that could revolutionize temperature sensing in industrial and biological applications, researchers have successfully created a 3D-printed temperature sensor with remarkable sensitivity. The sensor, developed by Fernando Rivera-López and his team at the Universidad de La Laguna in Spain, combines an optically active Gd3NbO7:Yb3+, Tm3+ powder with a 3D-printed probe UV photo-curable resin. This innovation opens new avenues for remote temperature monitoring, particularly in environments where traditional sensors fall short.

The sensor’s unique design allows it to function effectively in both 2-propanol and water, two fluids of significant importance in various industries. “The ability to measure temperature accurately in different media is crucial for many industrial processes,” explains Rivera-López. “Our sensor provides high sensitivity and low uncertainty, making it a reliable tool for remote temperature sensing.”

The sensor’s performance was evaluated by immersing it in the two fluids and varying the temperature between 21.0°C and 50.0°C. In 2-propanol, the sensor demonstrated a maximum relative thermal sensitivity (Sr) of 2.15% K−1 at 22.8°C, with an uncertainty of 0.5K. In water, the sensor achieved an even higher sensitivity of 2.6% K−1 at 49.4°C, with an uncertainty of 0.2K. These results are particularly promising for applications in the energy sector, where precise temperature control is essential for efficiency and safety.

One of the most notable aspects of this research is the use of non-thermally-coupled levels (TCLs) for temperature sensing. “This is the first time that these Tm3+ non-TCLs have been investigated as a function of temperature for remote sensor purposes,” Rivera-López notes. This innovative approach could pave the way for new types of sensors with enhanced capabilities.

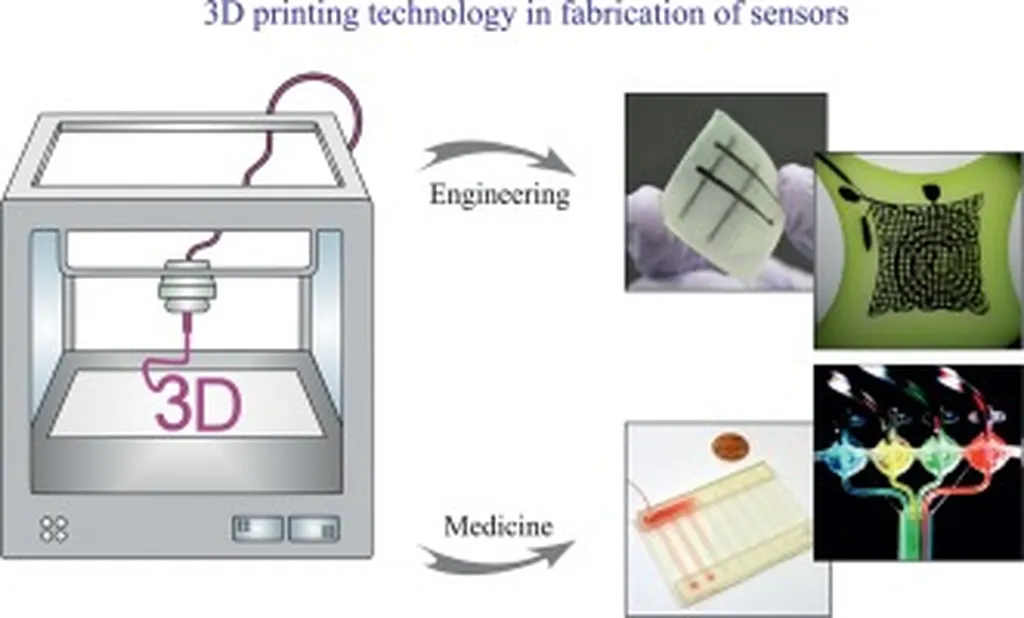

The sensor’s manufacture using 3D printing is another significant advancement. “3D printing allows for the creation of complex and customized sensor designs that would be difficult or impossible to achieve with traditional manufacturing methods,” Rivera-López explains. This flexibility could lead to the development of sensors tailored to specific industrial needs, further enhancing their utility.

The research, published in the journal Materials Today Advances (translated to English as “Advanced Materials Today”), highlights the potential of this new sensor technology. As industries continue to seek more efficient and accurate ways to monitor temperature, this innovation could play a crucial role in shaping the future of remote temperature sensing. The implications for the energy sector are particularly significant, where precise temperature control can lead to improved efficiency, reduced costs, and enhanced safety.

This breakthrough not only demonstrates the potential of 3D printing in sensor manufacturing but also underscores the importance of continued research and development in this field. As industries strive for greater precision and reliability in their temperature monitoring systems, innovations like this one will be essential in meeting those needs. The future of remote temperature sensing looks bright, and this research is a significant step forward in that direction.