In the quest to enhance the durability and efficiency of mechanical components, researchers have turned to an age-old process with a modern twist: boriding. A recent study published in the journal *Materials Research Express* (which translates to “Materials Research Express” in English) has shed new light on how this thermochemical treatment can significantly improve the wear resistance and reduce friction in steel components, offering promising implications for the energy sector.

Leopoldo García-Vanegas, a researcher at Tecnologico de Monterrey’s School of Engineering and Sciences, led a team that investigated the effects of boriding on AISI M2 steel substrates. The process involves treating the steel with boron at high temperatures to form a biphasic boride layer, which enhances the material’s surface properties.

“Boriding is a surface hardening process that has been around for decades, but its full potential has not been thoroughly explored,” García-Vanegas explained. “Our study aimed to understand how different boriding conditions affect the wear and friction behavior of steel, which is crucial for improving the performance and longevity of mechanical components.”

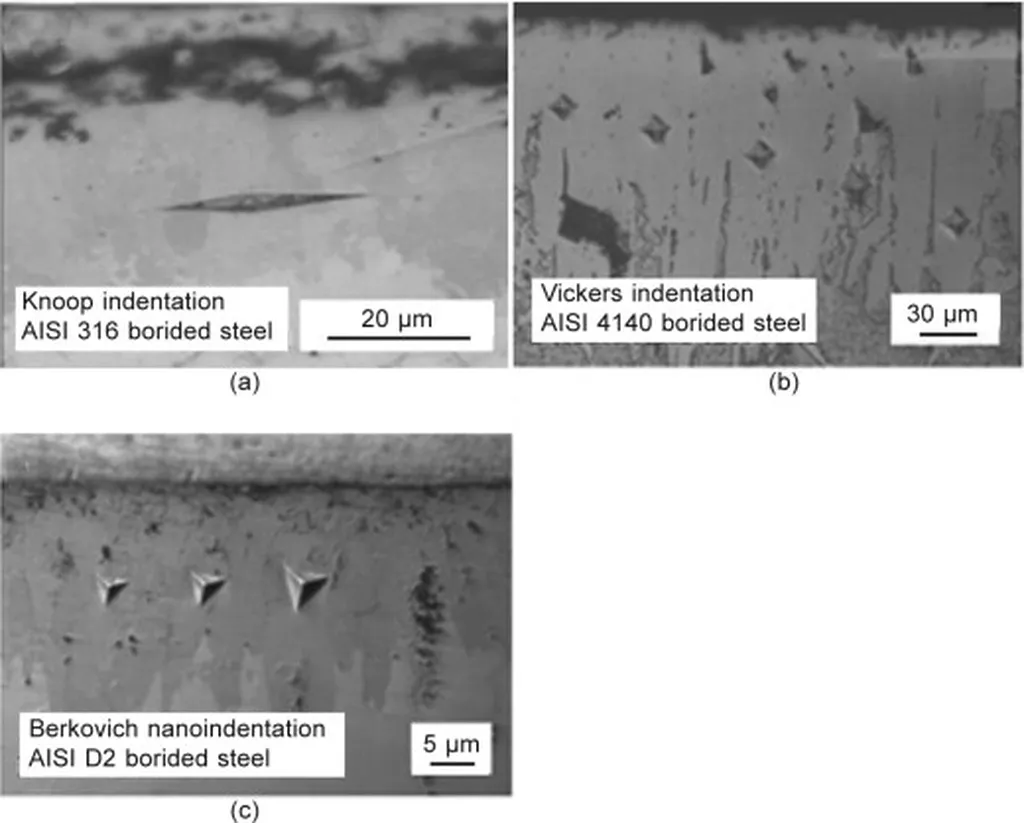

The researchers used the powder pack technique to apply the boriding treatment at various temperatures and exposure times. They then characterized the resulting boride layers using advanced techniques such as x-ray diffraction, scanning electron microscopy (SEM), nanoindentation, and contact profilometry. To evaluate the wear and friction properties, they conducted pin-on-disc tests under dry conditions, using an alumina (Al2O3) ball in contact with both unborided and borided steel surfaces.

The results were compelling. The study found a linear relationship between the surface hardness and wear depth of the boride layer, indicating that harder surfaces exhibit better wear resistance. “This relationship is crucial for predicting the performance of borided components in real-world applications,” García-Vanegas noted.

The researchers also discovered that boriding significantly reduced the coefficient of friction compared to unborided steel. While the unborided substrate had a friction coefficient of 0.81, the borided substrates ranged from 0.70 to 0.77. This reduction in friction can lead to substantial energy savings in mechanical systems, as less energy is lost to overcome friction.

However, the study also identified specific boriding conditions—1173 K for 6 hours, 1223 K for 4 hours, and 1223 K for 8 hours—that resulted in lower wear resistance. This finding highlights the importance of optimizing boriding parameters to achieve the best possible performance.

The implications of this research are far-reaching, particularly for the energy sector. Mechanical components in energy systems, such as turbines, pumps, and compressors, often operate under high-stress conditions that lead to wear and friction. By applying boriding treatments, these components can be made more durable and efficient, reducing maintenance costs and energy consumption.

García-Vanegas envisions a future where boriding is more widely adopted in the industry. “As we continue to refine the boriding process and understand its effects on different materials, we can develop more robust and efficient mechanical components. This will not only benefit the energy sector but also other industries that rely on high-performance materials.”

The study’s findings, published in *Materials Research Express*, provide a solid foundation for further research and development in the field of surface engineering. As the demand for more efficient and sustainable energy solutions grows, innovations like boriding will play a crucial role in shaping the future of mechanical engineering.

In the words of García-Vanegas, “This research is just the beginning. There is still much to explore and many opportunities to improve the performance of mechanical components through advanced surface treatments.”