In a groundbreaking development poised to revolutionize industries reliant on transparent materials, researchers have unveiled a novel method to imbue rigid polyurethane (PU) with both superhydrophobic and slippery liquid-infused porous surface (SLIPS) properties. This innovation, spearheaded by Hyun-Sung Kim from the Department of Mechanical Engineering at Chosun University in Gwangju, South Korea, opens new avenues for applications in displays, optical sensors, and medical devices, with significant implications for the energy sector.

The study, published in the journal *Applied Surface Science Advances* (translated as *Advances in Applied Surface Science*), addresses a longstanding challenge in the industry: the lack of transparency in conventional superhydrophobic and SLIPS materials. “Our approach not only enhances the durability and optical properties of rigid polyurethane but also introduces a new level of functionality that can be tailored to specific industrial needs,” Kim explained.

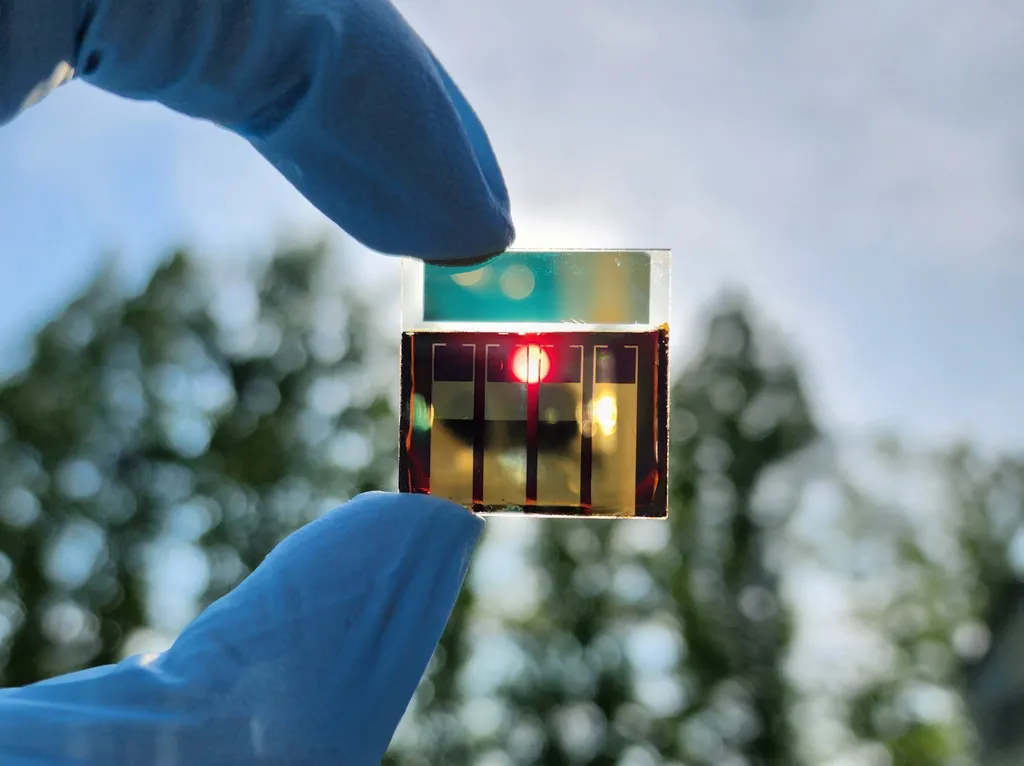

The research team developed a unique surface processing technique that involves etching and functionalizing aluminum to create a superhydrophobic structure. This structure is then replicated onto rigid, transparent PU using a polydimethylsiloxane mold. To achieve the SLIPS property, the superhydrophobic PU is infused with a lubricant. The transparency of the SLIPS can be controlled by adjusting the refractive index difference between the PU substrate and the lubricant, with silicone oil proving to be an effective choice for high optical transmittance.

The implications for the energy sector are profound. Transparent, durable, and self-cleaning surfaces could enhance the efficiency and longevity of solar panels, which often suffer from reduced performance due to dirt and moisture accumulation. “Imagine solar panels that remain clean and efficient with minimal maintenance, or optical sensors that operate flawlessly in harsh environments,” Kim envisioned. “This technology has the potential to significantly impact the energy sector by improving the performance and durability of critical components.”

Moreover, the ability to control transparency opens up possibilities for advanced display technologies and medical devices that require both optical clarity and robust surface properties. The versatility of this new approach means it can be adapted to a wide range of applications, from consumer electronics to industrial equipment.

As the world increasingly demands sustainable and high-performance materials, this research represents a significant step forward. By combining superhydrophobic and SLIPS properties with transparency, the team has created a material that could redefine the standards for functional surfaces. The study not only highlights the potential for innovation in material science but also underscores the importance of interdisciplinary collaboration in driving technological advancements.

In the words of Kim, “This is just the beginning. The possibilities are vast, and we are excited to explore how this technology can be further developed and applied in various industries.” As researchers continue to push the boundaries of material science, the future of transparent, durable, and functional surfaces looks brighter than ever.