In the quest to reduce emissions and recycle mineral waste, researchers are turning to an unlikely hero: concrete fines. A recent study led by Jan P. Höffgen from the Karlsruhe Institute of Technology (KIT) has shed new light on how thermally activated concrete fines can substitute cement, potentially revolutionizing the construction industry and offering significant benefits to the energy sector.

Concrete fines, a byproduct of waste recycling, have long been a challenge due to their variable compositions and impact on compressive strength. Höffgen’s study, published in the journal ‘Developments in the Built Environment’ (translated as ‘Advances in the Built Environment’), explores this issue in depth. The journal focuses on innovative research in the built environment, making it a fitting home for this groundbreaking work.

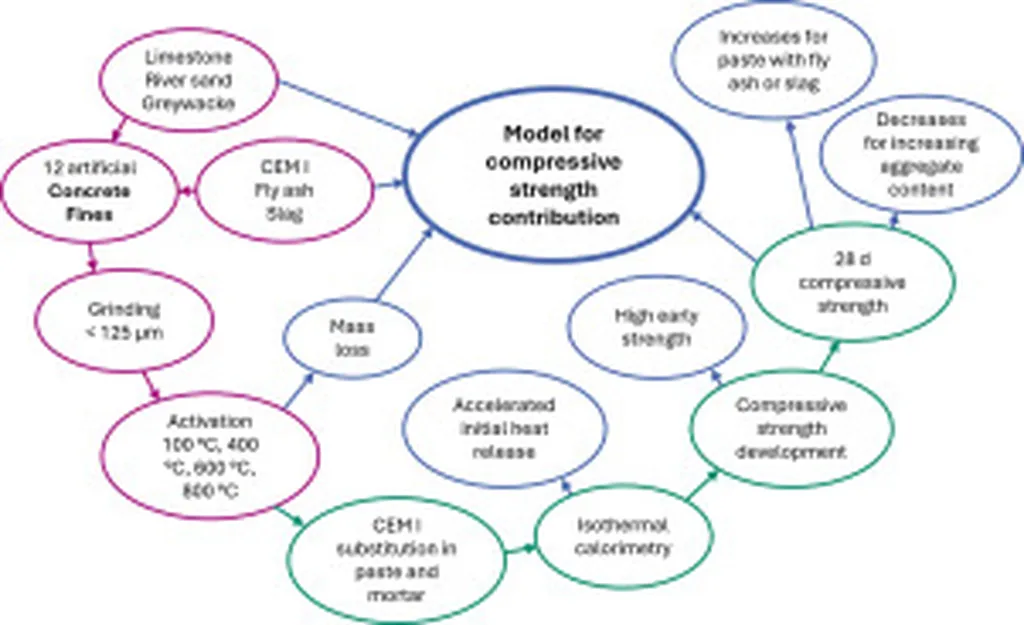

Höffgen and his team created 12 artificial concrete fines with varying compositions and thermally activated them to assess their strength contribution. Their findings were eye-opening. “We found that increasing aggregate content within artificial fines results in a decrease in compressive strength,” Höffgen explained. “However, the aggregate mineralogy and binder composition have a major impact on this outcome.”

The study proposes a model for predicting the impact of fines composition on compressive strength based on mass loss during dehydration. This model suggests that thermally activated cement paste has no influence on compressive strength compared to the reference (k=1.0). Even more intriguing, paste precursors containing hydration products from alternative binders may surpass the reference (k>1.0), while an increasing amount of inert aggregates reduces strength (k<1.0). So, what does this mean for the construction and energy sectors? The potential is immense. By recycling mineral waste and reducing the need for cement, this research could lead to significant emissions reductions. It also opens the door to more sustainable construction practices, which could have a ripple effect on energy consumption and environmental impact. Höffgen's work is a testament to the power of innovative thinking in tackling global challenges. As the world grapples with climate change and resource depletion, research like this offers a beacon of hope. It's a reminder that even the most mundane materials, like concrete fines, can hold the key to a more sustainable future. The study's findings could shape future developments in the field, paving the way for more efficient and eco-friendly construction practices. As the industry continues to evolve, research like this will be crucial in driving progress and innovation.