In the quest for sustainable construction materials, a groundbreaking study published in the journal *Discover Materials* (translated from Russian as “Find Materials”) is making waves. Researchers have uncovered a novel approach to soil stabilization that not only promises significant cost savings but also offers substantial environmental benefits. At the heart of this innovation is the use of fly ash and red mud, two industrial byproducts, to create geopolymers—an eco-friendly alternative to traditional Portland cement.

Rohit Raj, a lead author from the Department of Civil Engineering at BIT Sindri (under Jharkhand University of Technology, Ranchi), explains, “The utilization of industrial wastes for soil stabilization and building provides significant cost savings, environmental advantages, and social enhancements.” This research marks a departure from previous studies by examining the combined effects of fly ash and red mud on soil stabilization, rather than focusing on each precursor separately.

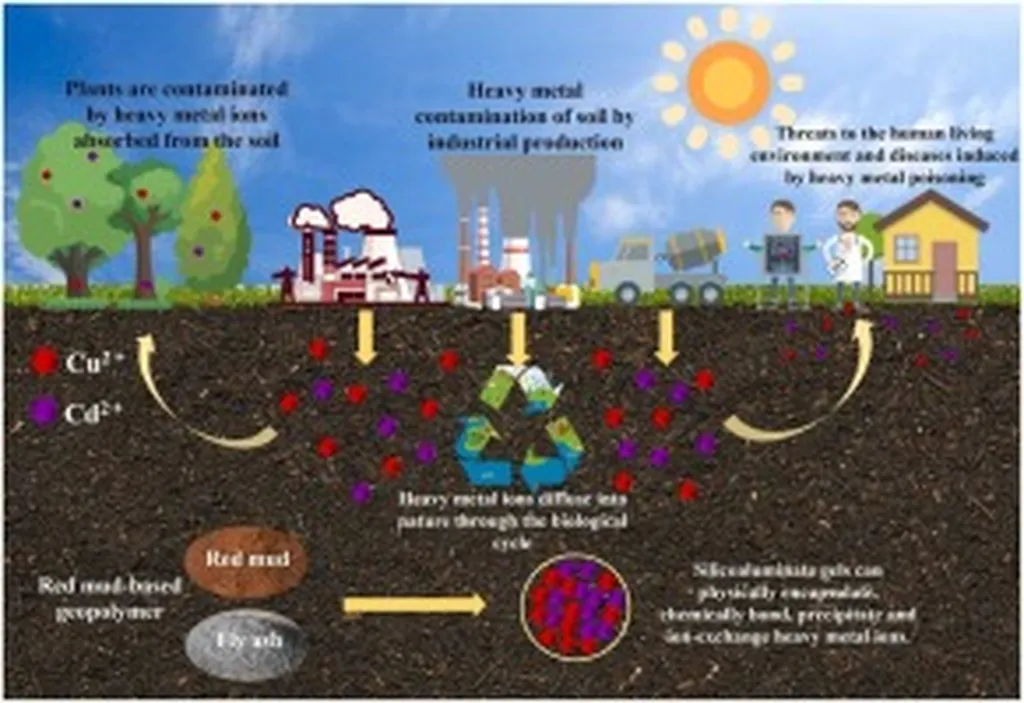

Geopolymers, which are amorphous alkali-activated binders, have gained attention for their potential to reduce carbon dioxide emissions and improve environmental efficacy. The study delves into the chemical reactions and mechanisms involved in geopolymerization, exploring how these materials interact with different soil types. The findings reveal that fly ash-red mud geopolymers can significantly enhance soil strength and durability, even under diverse loading and environmental conditions.

One of the most compelling aspects of this research is its practical applications. Case studies demonstrate the efficacy of fly ash-red mud geopolymers in real-world geotechnical projects, showcasing their potential to revolutionize soil stabilization methods. “This research investigates the combined impacts of fly ash and red mud on soil stabilization,” Raj notes, highlighting the unique synthesis of combined effects on soil behavior, chemical interactions, and engineering performances.

The environmental and economic benefits of this approach are substantial. By utilizing industrial wastes, the method not only reduces the need for traditional stabilizers but also minimizes the environmental footprint of construction projects. This is particularly relevant for the energy sector, where large-scale infrastructure projects often require extensive soil stabilization.

However, the study also identifies significant challenges and research gaps that need to be addressed. Future research directions are outlined to enhance the utilization of sustainable geopolymer technology in soil stabilization. As the construction industry continues to seek innovative and sustainable solutions, this research offers a promising path forward.

In the words of Rohit Raj, “Future research directions are outlined to enhance the utilization of sustainable geopolymer technology in soil stabilization.” This study not only advances our understanding of geopolymers but also paves the way for more sustainable and cost-effective construction practices. As the industry looks to the future, the insights gained from this research could shape the development of new materials and techniques, ultimately transforming the way we build and stabilize the ground beneath our feet.