In the quest for materials that can simultaneously handle impact and dissipate heat, researchers have turned to an unusual pairing: aluminum foam and paraffin. A recent study led by Ningzhen Wang from the School of Technology at Beijing Forestry University has uncovered promising insights into the mechanical properties of these composite foams, potentially revolutionizing industries that demand robust, lightweight, and thermally efficient materials.

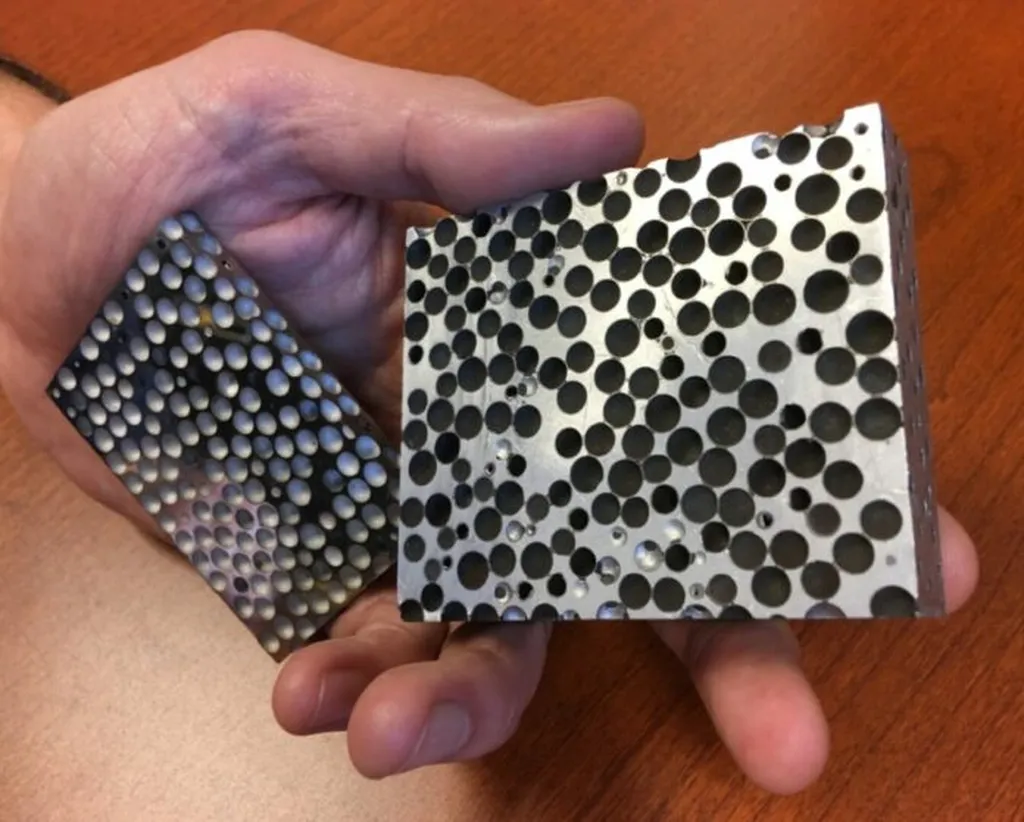

Aluminum foams, known for their lightweight and energy-absorbing capabilities, have been infused with paraffin, a phase change material, to create a composite that prevents paraffin from flowing out after melting. This combination is particularly appealing for applications in the energy sector, where both impact resistance and efficient heat dissipation are crucial.

The study, published in *Materials & Design* (translated as *Materials & Design*), reveals that the mechanical properties of these composite foams exhibit a slight decrease under quasi-static compression but show a significant improvement—around 30%—under dynamic loading at 5 meters per second. “The addition of paraffin enhances the strain rate sensitivity and reduces the influence of foam density on composite performance,” explains Wang. This means that the material becomes more adaptable to different loading conditions, making it ideal for a range of applications.

The research involved both experimental and numerical analyses based on Kelvin tetradecahedron structures. The numerical analysis showed that the plateau stress of the composite foam decreased from 6.89 MPa to 6.11 MPa under quasi-static conditions but increased from 10.46 MPa to 13.65 MPa under dynamic compression. These findings are consistent with the experimental results, providing a robust foundation for future material design.

The implications for the energy sector are substantial. Lightweight, energy-absorbing, and thermally conductive materials are in high demand for various applications, from renewable energy systems to advanced manufacturing processes. The ability to tailor the mechanical properties of these composite foams could lead to more efficient and durable solutions, ultimately reducing costs and improving performance.

As the world continues to seek innovative materials to meet the challenges of the 21st century, the work of Wang and his team offers a glimpse into the future of advanced materials. By combining the strengths of aluminum foams and phase change materials, they have opened new avenues for research and development, paving the way for materials that are not only strong and lightweight but also capable of managing heat effectively. This research could shape the future of energy-efficient and impact-resistant materials, making it a significant step forward in the field.