In the ever-evolving world of construction and infrastructure, a groundbreaking study has emerged that could significantly impact the seismic rehabilitation of reinforced concrete (RC) shear walls. Led by Mehdi Khorasani from the Department of Civil Engineering at Isfahan University of Technology in Iran, this research introduces a hybrid repair strategy that combines ultra-high-performance concrete (UHPC) and fiber-reinforced polymer (FRP) strips, installed using the externally bonded reinforcement on grooves (EBROG) technique with FRP anchors. The findings, published in the open-access journal ‘Composites Part C: Open Access’ (translated as ‘Composites Part C: Open Access’), offer promising solutions for enhancing the resilience of structures in earthquake-prone regions.

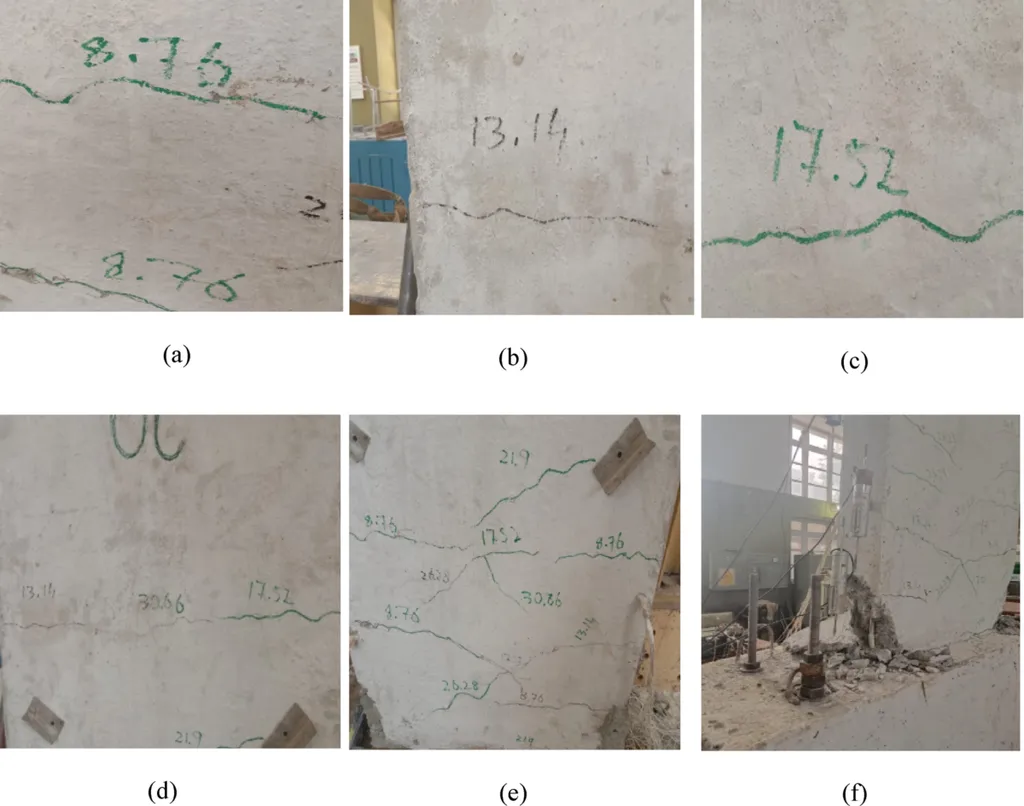

The study involved testing three full-scale walls under cyclic lateral loading: a reference wall (FCW), a UHPC-repaired wall (R-UHPC), and a hybrid UHPC–FRP wall (R-UHPC-FRP). The results were impressive. Both repair approaches effectively restored the walls’ strength, with the hybrid wall exceeding the control’s capacity by 13%. “The hybrid UHPC–FRP repair not only restored the strength but also improved the overall performance of the damaged walls,” Khorasani explained. However, the research also noted a decrease in ductility by 35–45% compared to the control, indicating a trade-off between strength and flexibility.

One of the most significant findings was the substantial recovery of energy dissipation in the hybrid system. At 2% drift, the hybrid wall achieved up to 90–95% of the control’s energy dissipation capacity. “This is a crucial aspect for structures in seismic zones, as it enhances their ability to absorb and dissipate energy during earthquakes,” Khorasani added. Stiffness retention was also improved, with the hybrid wall maintaining values comparable to the control beyond 1% drift. Despite lower hysteretic damping than the control, the hybrid wall showed improved damping at higher deformations, further highlighting its potential benefits.

The commercial implications of this research are substantial, particularly for the energy sector. Infrastructure such as power plants, refineries, and other critical facilities often require robust seismic protection to ensure continuous operation and safety. The hybrid UHPC–FRP repair method could provide a cost-effective and efficient solution for retrofitting existing structures, thereby reducing downtime and maintenance costs. Additionally, the enhanced energy dissipation and stiffness retention could lead to more resilient designs, minimizing the risk of structural failure during seismic events.

As the construction industry continues to seek innovative solutions for seismic rehabilitation, this research offers a promising avenue for future developments. The hybrid UHPC–FRP repair method, enhanced by the EBROG technique, could become a standard practice in the field, particularly in regions prone to earthquakes. “This study opens up new possibilities for improving the seismic performance of RC shear walls, and we are excited to explore further applications and refinements of this technique,” Khorasani concluded.

In conclusion, the research led by Mehdi Khorasani and his team at Isfahan University of Technology represents a significant advancement in the field of seismic rehabilitation. By combining UHPC and FRP strips with the EBROG technique, they have demonstrated a method that not only restores strength and stiffness but also substantially recovers energy dissipation. This innovation could have far-reaching implications for the construction and energy sectors, paving the way for more resilient and safer infrastructure in the future.