In the heart of Shanghai, researchers at Tongji University’s Department of Geotechnical Engineering have developed a groundbreaking model to tackle a pressing issue in the construction industry: accurately measuring carbon emissions from tunnel construction machinery. Led by Hongyang Liu, the team’s work, published in the journal *Cleaner Engineering and Technology* (translated from Chinese as *Cleaner Engineering and Technology*), promises to revolutionize how we understand and mitigate the environmental impact of tunnel construction.

The problem is clear: tunnel construction, particularly the drill-and-blast method, is a significant contributor to carbon emissions. However, current methods of calculating these emissions lack the precision needed to make informed decisions. Liu and his team set out to change that. “Our goal was to create a model that could provide timely and accurate carbon emission calculations for construction machinery in real-world projects,” Liu explains. The result is a sophisticated model that classifies machinery into different groups based on their function and the specific processes they’re involved in, considering factors like internal combustion engines, electric motors, and operational resistance.

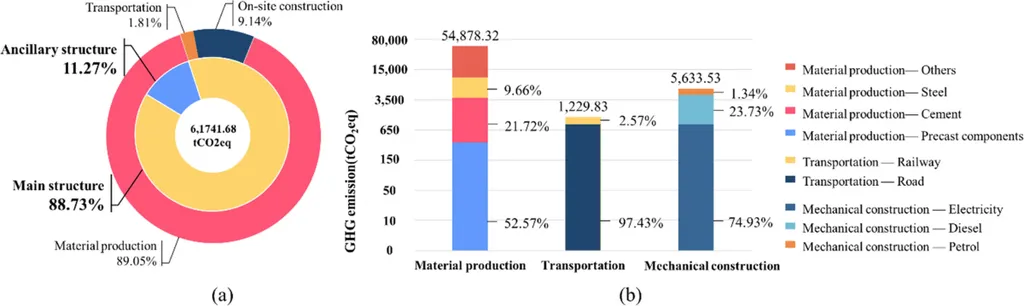

The model’s reliability was put to the test using real tunnel construction data. Through control variable comparisons, the team analyzed the impacts of slope, acceleration, and complex road conditions on mechanical carbon emissions. Their findings highlight the advantages of introducing new battery-based energy machinery compared to traditional fossil fuel machinery. “The benefits of new energy machinery are clear,” Liu notes. “They not only reduce carbon emissions but also offer significant advantages in terms of construction time and operational processes.”

The implications for the energy sector are substantial. As the world shifts towards cleaner energy solutions, the construction industry must adapt. This research provides a method for calibrating the carbon emissions of tunnel construction machinery, aiding in the selection of more environmentally friendly options. “This study helps us understand the environmental impact of construction and paves the way for subsequent research on machinery selection,” Liu says.

The commercial impacts are equally significant. Construction companies can use this model to make data-driven decisions, reducing their carbon footprint and potentially lowering operational costs. The energy sector can leverage this research to develop more efficient and environmentally friendly machinery, meeting the growing demand for sustainable construction practices.

As the world continues to grapple with the challenges of climate change, research like this offers a beacon of hope. By providing a clearer picture of the environmental impact of construction machinery, Liu and his team are helping to shape a more sustainable future. Their work not only advances our understanding of carbon emissions but also highlights the potential of new energy machinery in reducing our environmental footprint.

In an industry often resistant to change, this research could be a catalyst for transformation. As the construction sector faces increasing pressure to adopt greener practices, the insights provided by Liu’s team could prove invaluable. The journey towards sustainable construction is long and complex, but with innovative research like this, the path forward becomes a little clearer.