In the relentless pursuit of stronger, more resilient materials, researchers have turned to an unlikely ally: machine learning. A recent study published in *Materials Research Letters* (translated from Chinese as “Materials Research Letters”) has unveiled a groundbreaking approach to designing high-performance alloys, with significant implications for the energy sector. At the helm of this research is Ling Shen, a materials scientist from the College of Materials Science and Engineering at Hunan University in China.

The study focuses on body-centered cubic (BCC) high-entropy alloys (HEAs), a class of materials known for their exceptional strength and heat resistance. However, predicting and optimizing their mechanical properties have been challenging due to the complex interplay of various elements and parameters. This is where machine learning steps in.

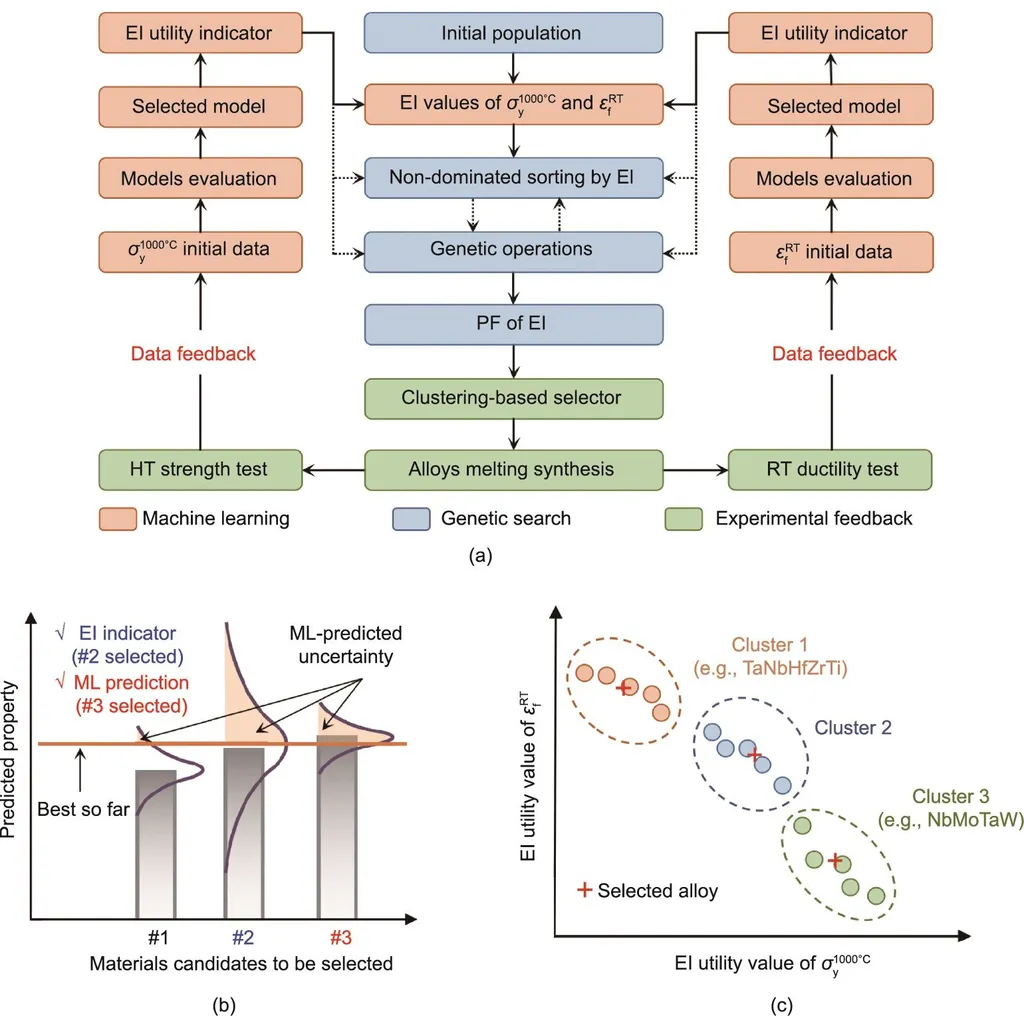

“We utilized machine learning-based feature importance analysis to systematically identify the critical material parameters and elemental effects governing the yield strength of BCC HEAs,” Shen explains. The team found that the shear modulus mismatch and the presence of molybdenum (Mo) significantly contribute to the yield strength of these alloys.

By adjusting the titanium-to-molybdenum content ratio, the researchers successfully developed an as-cast single-phase BCC refractory HEA with a yield strength of 1169.3 MPa and an elongation of 18.8%. This remarkable combination of strength and ductility is attributed to the activation of multiple slip systems within the material.

The implications of this research are profound, particularly for the energy sector. High-performance alloys are crucial for constructing power plants, turbines, and other energy infrastructure that operate under extreme conditions. The ability to design and optimize these materials efficiently could lead to more robust, durable, and cost-effective energy solutions.

“This research provides a new strategy for accelerating the design of HEAs with outstanding mechanical properties,” Shen notes. The use of machine learning not only speeds up the development process but also opens up new possibilities for exploring and understanding complex material behaviors.

As the energy sector continues to evolve, the demand for advanced materials that can withstand harsh environments and extreme temperatures will only grow. The integration of machine learning in materials science, as demonstrated in this study, could revolutionize the way we design and manufacture these critical components.

In the words of Shen, “Our findings pave the way for a new era in materials design, where data-driven approaches and advanced computational tools play a central role.” This research, published in *Materials Research Letters*, marks a significant step forward in that direction, offering a glimpse into a future where machine learning and materials science converge to create stronger, more resilient, and more efficient materials for the energy sector and beyond.