In a groundbreaking development poised to reshape the construction and energy sectors, researchers have unveiled a novel approach to enhance the strength and ductility of titanium (Ti) using additive manufacturing. This innovation, detailed in a recent study published in *Materials Research Letters* (translated to English as “Letters on Materials Research”), could pave the way for more robust and flexible materials tailored for demanding applications.

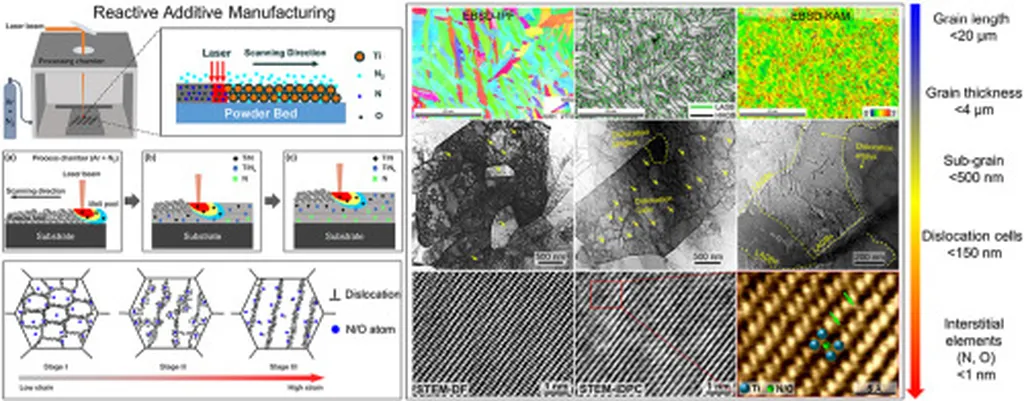

At the heart of this research is a sandwich-like hetero-lamellar structure, meticulously crafted by combining 3D printing and conventional manufacturing techniques. The result is a titanium plate with a layered, gradient microstructure that defies traditional material limitations. “By leveraging additive manufacturing, we can not only design components with complex geometries but also fine-tune their microstructures to achieve superior mechanical properties,” explains Jingyuan Shen, lead author of the study and a researcher at the Department of Civil and Mechanical Engineering, Technical University of Denmark.

The hetero-lamellar structure introduces varied deformation mechanisms across the plate’s thickness, significantly boosting its strain-hardening capacity. This breakthrough translates into a remarkable combination of strength and ductility, with the plate achieving an exceptional uniform elongation of 27%. Such properties are particularly valuable in industries where materials must withstand extreme conditions while maintaining flexibility.

For the energy sector, the implications are profound. Titanium’s enhanced strength and ductility could lead to more durable and efficient components in power generation and transmission systems. “Imagine turbines and pipelines that are not only stronger but also more adaptable to stress and strain,” Shen envisions. “This could revolutionize how we design and deploy infrastructure in the energy sector, making it more resilient and cost-effective.”

The study’s findings suggest that additive manufacturing could unlock new possibilities for material design, enabling engineers to create components with tailored properties for specific applications. As the technology continues to evolve, we can expect to see more innovations that push the boundaries of what’s possible in materials science.

This research, published in *Materials Research Letters*, underscores the transformative potential of additive manufacturing in the energy sector and beyond. By harnessing the power of 3D printing and conventional manufacturing, researchers are paving the way for a future where materials are not just stronger but also more adaptable to the demands of modern industry. As Shen notes, “This is just the beginning. The possibilities are endless.”