In the quest for stronger, more adaptable steels, researchers have long explored the transformative potential of annealing temperatures on TRIP (Transformation Induced Plasticity) steels. A recent study published in *Teshugang* (which translates to “Iron and Steel” in English) sheds new light on how subtle changes in annealing temperatures can significantly alter the microstructure of these advanced materials, with profound implications for industries like energy, automotive, and construction.

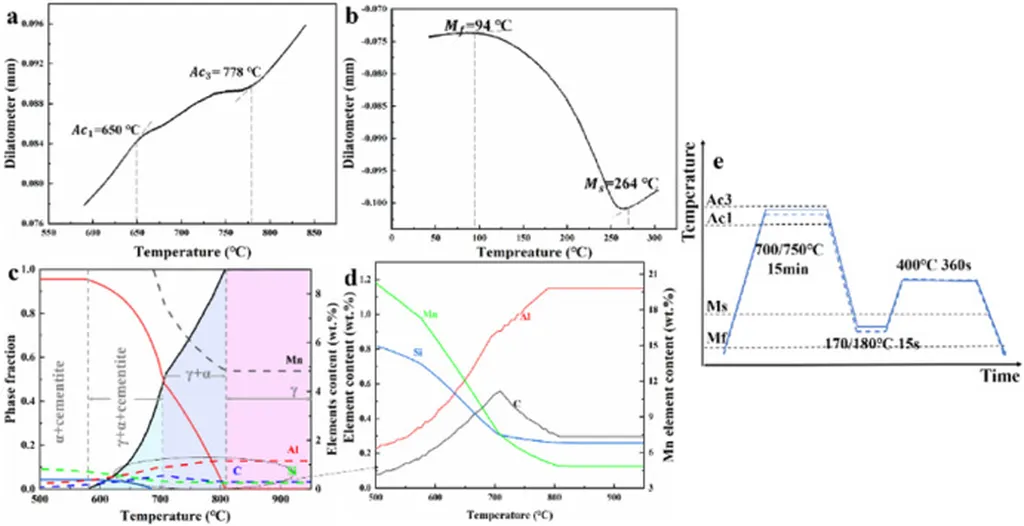

The research, led by Jing Cainian, delves into the effects of annealing temperatures ranging from 750°C to 780°C on two types of TRIP steel: 0.2C-1.5Si-1.5Mn and 0.2C-1.5Si-1.5Mn-0.5Cu. Using color metallography, X-ray diffraction, and scanning electron microscopy, the team uncovered critical insights into how these temperatures influence the volume fractions of retained austenite, ferrite, and bainite.

“Our findings reveal that the addition of copper significantly enhances the stability of retained austenite,” Jing Cainian explained. “For the TRIP steel containing 0.5% copper, the retained austenite volume fraction remained remarkably stable at around 16.2% to 17.2% across most annealing temperatures, except at 770°C, where it dipped slightly to 15.2% to 15.7%.” This stability is crucial for applications requiring high ductility and strength, such as in the manufacturing of pipelines and structural components for the energy sector.

In contrast, the TRIP steel without copper showed more variability. At 760°C and 770°C, the retained austenite volume fraction was lower, ranging from 12.5% to 15.1%. However, at 750°C and 780°C, it increased to 17.0% to 17.5% and 16.0% to 16.4%, respectively. This variability suggests that the absence of copper makes the steel more sensitive to changes in annealing temperature, which could complicate its use in applications requiring precise mechanical properties.

The study also found that as the annealing temperature increased from 750°C to 780°C, the ferrite volume fraction decreased from approximately 70% to 50%, while the bainite volume fraction increased from around 10% to 30%. These changes in microstructure are critical for tailoring the mechanical properties of TRIP steels to specific industrial needs.

The implications of this research are far-reaching. For the energy sector, understanding how to optimize the annealing process can lead to the development of steels that are not only stronger and more durable but also more cost-effective. “By fine-tuning the annealing temperature, we can achieve the desired balance of strength and ductility, making these steels ideal for high-stress applications,” Jing Cainian noted.

As industries continue to push the boundaries of material science, this research highlights the importance of precise control over manufacturing processes. The findings published in *Teshugang* provide a roadmap for future developments in TRIP steel technology, offering a glimpse into a future where materials are not just stronger but also more adaptable to the ever-evolving demands of modern industry.