In the realm of advanced materials science, a groundbreaking study published in the journal *Teshugang* (translated to “Iron and Steel” in English) has unveiled the potential of mechanical alloying to produce nano-crystalline ultrafine grain materials. This research, led by He Hang, offers a glimpse into the future of material properties and their applications, particularly in the energy sector.

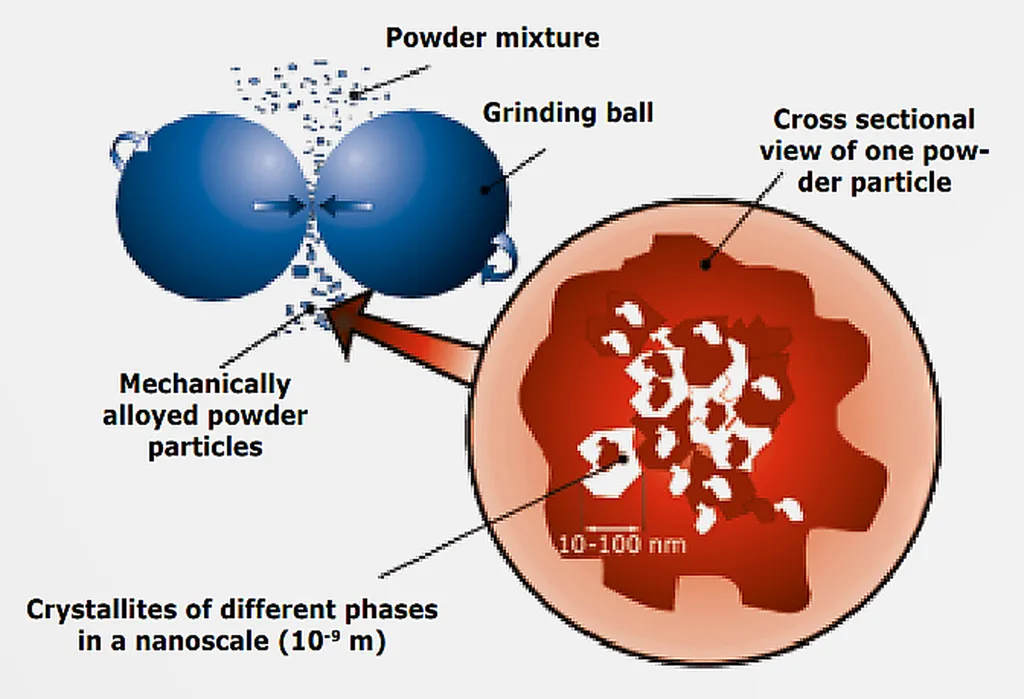

Mechanical alloying, a solid-state technology, has been gaining traction for its ability to create materials with exceptional properties. He Hang’s work delves into the development and process of this technology, highlighting its success in producing nano-crystalline ultrafine grain dispersion strengthened materials, magnetic materials, superconducting materials, and nano-crystalline materials.

The study presents a comprehensive overview of the mechanical, magnetic, and hydrogen storage properties of these advanced materials. “The potential of mechanical alloying to produce materials with enhanced properties is immense,” says He Hang. “This technology could revolutionize the energy sector by providing materials that are stronger, more durable, and more efficient.”

The implications for the energy sector are significant. Nano-crystalline materials produced through mechanical alloying could lead to more efficient energy storage systems, improved magnetic materials for generators and motors, and advanced superconducting materials for power transmission. These advancements could pave the way for more sustainable and efficient energy solutions.

He Hang’s research also explores the potential for these materials to be used in hydrogen storage, a critical component in the development of clean energy technologies. “The ability to store hydrogen efficiently is a key challenge in the transition to a hydrogen economy,” explains He Hang. “Our findings suggest that nano-crystalline materials produced through mechanical alloying could offer a viable solution.”

The study published in *Teshugang* not only highlights the current capabilities of mechanical alloying but also points to future developments in the field. As He Hang notes, “The potential for further innovation in this area is vast. We are just scratching the surface of what is possible with mechanical alloying.”

In the ever-evolving landscape of materials science, He Hang’s research stands as a testament to the power of innovation. By pushing the boundaries of what is possible, this study opens new avenues for exploration and development, ultimately shaping the future of the energy sector.