In a significant stride towards sustainable construction, researchers have developed a high-performance, lightweight concrete reinforced with waste copper fibers, offering a promising alternative to traditional concrete and micro-steel fibers. This innovation, led by Samer Abdulhussein from the School of Civil Engineering at Universiti Sains Malaysia and the Civil Engineering Department at Mustansiriyah University in Iraq, could revolutionize the energy sector by enhancing thermal insulation and reducing the carbon footprint of buildings.

The study, published in the *Journal of Engineering and Sustainable Development* (translated to English as *Journal of Engineering and Sustainable Development*), explores the use of waste copper fibers derived from damaged electronic and electrical devices as a sustainable and cost-effective reinforcement for aerated-polystyrene lightweight concrete. This approach not only addresses the growing concern of electronic waste but also provides a viable solution for the construction industry seeking to meet stringent environmental standards.

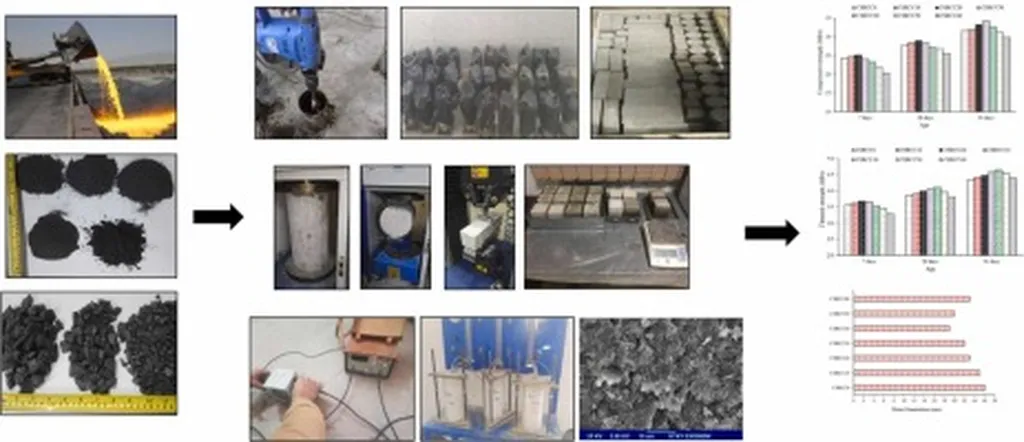

Abdulhussein and his team prepared eight different mixtures of aerated-polystyrene lightweight concrete, each reinforced with varying ratios of micro-steel fibers and waste copper fibers. The results were impressive, with the maximum compressive strength of the concrete reinforced by micro-steel fibers reaching 56.9 MPa and that reinforced by waste copper fibers achieving 55.9 MPa. The density of the concrete was also notably low, at a maximum of 1917 Kg/m3, making it an ideal material for lightweight construction.

“The originality of this research lies in the adoption of waste copper fibers as a sustainable, free-cost fiber,” Abdulhussein explained. “This innovation not only reduces the cost of production but also contributes to the circular economy by repurposing electronic waste.”

The implications of this research for the energy sector are substantial. Buildings constructed with this lightweight, high-performance concrete can benefit from improved thermal insulation, leading to reduced energy consumption for heating and cooling. This, in turn, can lower greenhouse gas emissions and help mitigate the effects of global warming.

Moreover, the use of waste copper fibers as a reinforcement material sets a precedent for future research and development in the field of sustainable construction. As Abdulhussein noted, “This study opens up new avenues for exploring the potential of other waste materials in construction, paving the way for a more sustainable and eco-friendly future.”

The research also highlights the importance of interdisciplinary collaboration, bringing together experts from civil engineering and materials science to address pressing environmental challenges. By leveraging the unique properties of waste copper fibers, this study demonstrates the potential of innovative materials to transform the construction industry and contribute to a more sustainable built environment.

As the world continues to grapple with the impacts of climate change, the development of high-performance, sustainable construction materials becomes increasingly critical. Abdulhussein’s research offers a promising solution, one that not only meets the structural criteria for lightweight concrete but also aligns with the growing demand for environmentally responsible building practices.