In the quest to keep our ever-more-powerful processors from overheating, a team of researchers from the Belarusian State University of Informatics and Radioelectronics has uncovered some intriguing insights that could reshape how we design cooling systems for high-performance computing and other energy-intensive applications. At the heart of this research is the humble heat pipe, a simple yet effective tool for transferring heat away from sensitive components.

The study, led by G. A. Piskun, delves into the influence of heat pipe length and quantity on the efficiency of removing excess thermal energy from modern processors. The findings, published in the Belarusian journal ‘Весці Нацыянальнай акадэміі навук Беларусі: Серыя фізіка-тэхнічных навук’ (translated as ‘Proceedings of the National Academy of Sciences of Belarus: Series of Physical and Technical Sciences’), offer valuable insights for engineers and designers looking to optimize cooling systems in various technical devices.

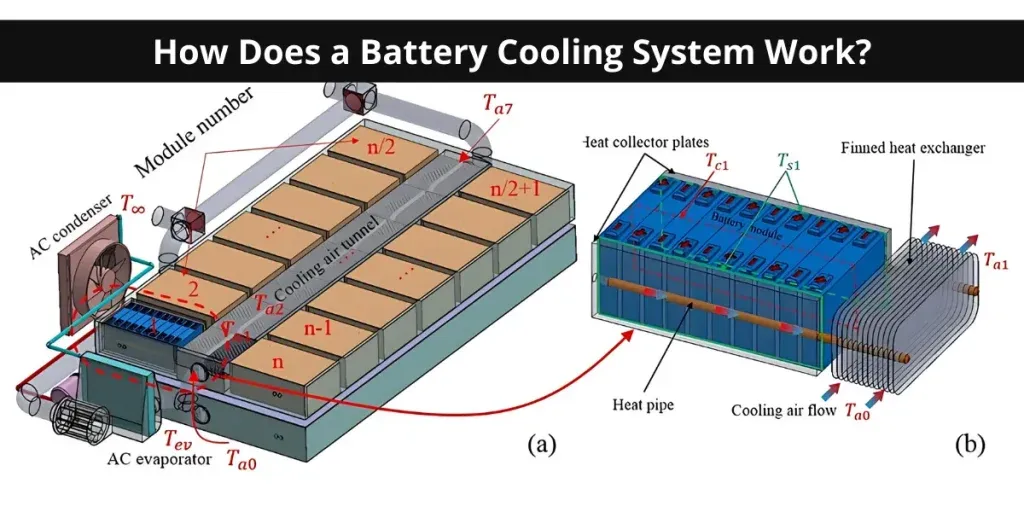

The research team conducted numerical modeling using the Flow Simulation module of the SolidWorks software package. They examined radiator constructions consisting of a heat sink, a heat pipe, and a finned radiator, placed in both open and closed environments. The open environment simulates air movement without mixing, typical of free convection, while the closed environment mimics natural convection in a limited space.

One of the key findings is that the temperature difference at the ends of heat pipes (referred to as HP) significantly depends on the natural movement of air flows in these environments. “We found that increasing the length of the HP from 100 mm to 500 mm leads to a notable increase in the temperature difference, both in open and closed environments,” Piskun explained. For instance, with a single heat pipe of 6 mm diameter and a processor power of 50 W, the temperature difference increased by 29.54 °C in an open environment and 47.14 °C in a closed environment.

The study also revealed that increasing the number of heat pipes from one to five, each with a diameter of 6 mm and a length of 500 mm, leads to a decrease in temperature difference. For the same processor power, the temperature difference dropped from 36.17 °C to 6.3 °C in an open environment and from 55.59 °C to 11.56 °C in a closed environment when using five heat pipes instead of one.

These findings have significant implications for the energy sector and other industries reliant on high-performance computing. As processors become more powerful, the need for efficient cooling solutions becomes ever more critical. The research suggests that by carefully selecting the length and number of heat pipes, engineers can design more effective cooling systems that enhance performance and reliability.

Piskun’s team believes their results can be applied to modernize cooling systems in various technical devices based on processors and to design new high-performance equipment. “Our findings provide a solid foundation for optimizing heat pipe configurations in cooling systems,” Piskun noted. “This can lead to more efficient energy use and better performance in a wide range of applications.”

As the demand for high-performance computing continues to grow, the insights from this research could pave the way for more innovative and efficient cooling solutions. By leveraging the principles outlined in this study, engineers can develop systems that not only keep processors cool but also contribute to the overall energy efficiency of the devices they power. This research is a testament to the ongoing efforts to push the boundaries of thermal management, ensuring that our technology remains reliable and efficient in an increasingly digital world.