In the world of aerodynamic engineering, the devil is often in the details, and a recent study published in the *Bulletin of the National Academy of Sciences of Belarus: Series of Physical and Technical Sciences* is shedding new light on the intricacies of jet nozzle design. The research, led by A. Ph. Ilyushchanka of the State Research and Production Powder Metallurgy Association, delves into the methods of determining gas-dynamic characteristics of jet nozzles, a critical component in the efficiency of aerodynamic objects with jet engines.

The study highlights the importance of nozzle parameters in the overall design and performance of jet engines, particularly in relation to the energy source and the working medium. “The efficiency of aerodynamic objects with jet engines is greatly influenced by nozzle parameters,” Ilyushchanka explains. “This makes it crucial to accurately calculate these characteristics at various stages of design and testing.”

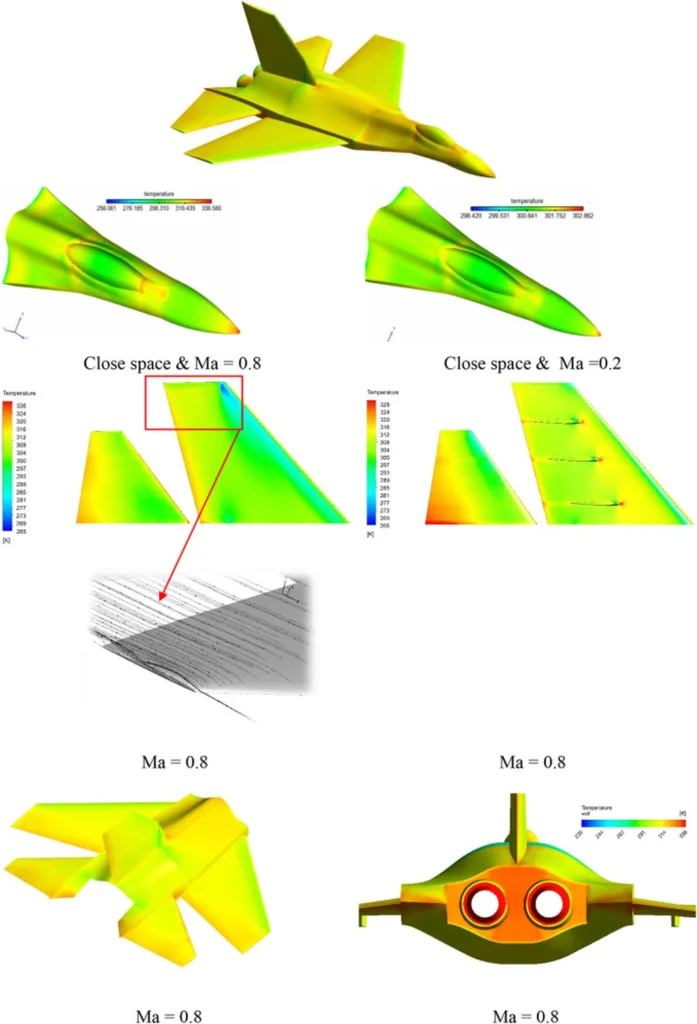

The research compares two primary methods of modeling nozzle performance: one-dimensional nozzle theory and gas dynamics modeling. The one-dimensional theory, while simpler and less computationally intensive, involves a large number of assumptions. On the other hand, gas dynamics modeling is more detailed, taking into account a greater number of factors but requiring more resources.

The study found a 6% difference in the results of various parameters between the two methods. Interestingly, the experimental data aligned more closely with the predictions made by the gas dynamics modeling method. However, Ilyushchanka notes that from a practical standpoint, the one-dimensional theory might be more advantageous for initial calculations due to its simplicity and lower cost. “It is advisable to give preference to one-dimensional theory to calculate the engine construction and to verify calculations with the use of the modeling methods,” Ilyushchanka suggests.

The findings of this research have significant implications for the energy sector, particularly in the design and optimization of jet engines. By understanding the nuances of nozzle performance, engineers can enhance the efficiency and effectiveness of aerodynamic objects, leading to better performance and reduced energy consumption.

As the field of aerodynamic engineering continues to evolve, this research provides valuable insights that could shape future developments. The balance between simplicity and detail in modeling methods will be crucial in advancing the design and performance of jet engines, ultimately driving innovation in the energy sector.

In the quest for more efficient and effective aerodynamic objects, every detail matters. And as this research shows, the seemingly small differences in modeling methods can have a significant impact on the performance of jet engines, paving the way for future advancements in the field.