In the pursuit of precision and reliability in material testing, a groundbreaking study led by Mehdi Moayyedian from the College of Engineering and Technology at the American University of the Middle East has shed new light on optimizing the hardness testing process for brass. Published in the journal *Discover Materials* (translated to English as “Exploring Materials”), this research combines the Taguchi method with Analysis of Variance (ANOVA) to enhance the consistency and accuracy of hardness measurements, a critical factor for industries relying on brass components.

Hardness testing is a fundamental process in material science, particularly in sectors like energy, where brass is widely used for its corrosion resistance and durability. However, variations in testing parameters can lead to inconsistent results, affecting quality control and material performance assessments. Moayyedian’s study addresses this challenge by systematically evaluating four critical parameters: indentation location, dwell time, temperature, and loading time.

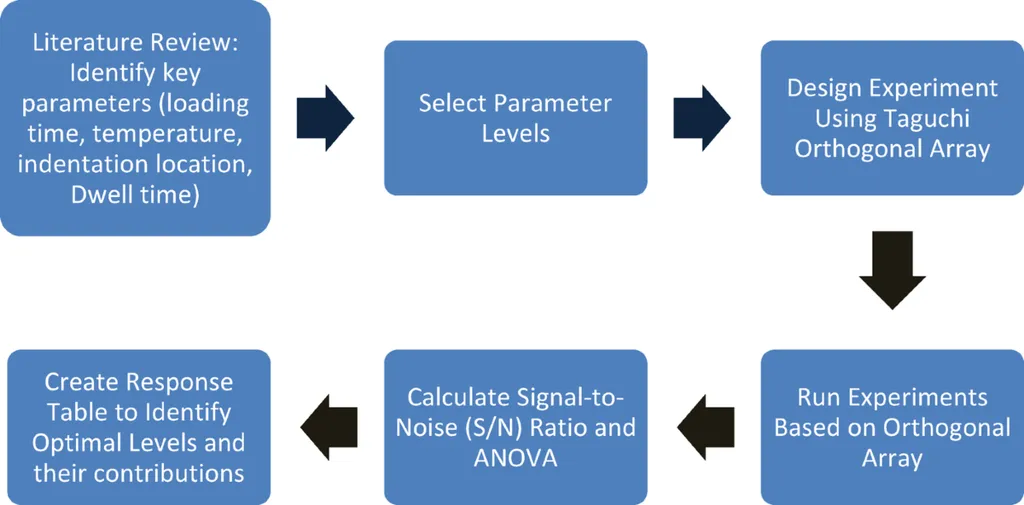

The research employed the Taguchi method, a robust design of experiments (DOE) approach, to identify the optimal levels for each parameter. “By using the Signal-to-Noise (S/N) ratio, we were able to pinpoint the most effective settings,” Moayyedian explained. The findings revealed that dwell time had the most significant impact on hardness values, contributing 38.21% to the overall variation, followed by temperature at 34.22%, loading time at 17.87%, and indentation location at 9.70%.

ANOVA further validated these results, providing a statistical foundation for the observed trends. “This methodical approach not only improves the accuracy of hardness testing but also offers practical insights for quality improvement in material testing,” Moayyedian added.

The implications of this research are far-reaching, particularly for the energy sector. Brass is a key material in various energy applications, from pipelines to renewable energy components. Ensuring the reliability of hardness testing can enhance the performance and longevity of these components, ultimately contributing to safer and more efficient energy systems.

Visual representations through pie and line charts further supported the analysis, making the data more accessible and interpretable. This study not only optimizes the hardness testing process but also sets a precedent for future research in material science. As industries continue to demand higher standards of quality and precision, the integration of advanced statistical methods like the Taguchi method and ANOVA will be crucial in meeting these expectations.

In the words of Moayyedian, “This systematic approach effectively optimizes hardness testing procedures for brass, offering practical insights for quality improvement in material testing.” The research, published in *Discover Materials*, is a testament to the power of innovative methodologies in driving progress in the field of material science. As the energy sector evolves, such advancements will play a pivotal role in shaping the future of material testing and quality assurance.