In the quest for sustainable and high-performance materials, researchers have turned to an unlikely duo: Abutilon indicum (AI) and okra fibers. A recent study, led by C. M. Mohanraj from the Department of Mechanical Engineering at Government College of Engineering, Bargur, Krishnagiri, Tamil Nadu, India, has unveiled the promising potential of hybrid AI and okra fiber-reinforced epoxy composites. The findings, published in the Journal of Engineered Fibers and Fabrics (which translates to “Journal of Engineered Fibers and Fabrics”), could pave the way for innovative applications in various industries, including the energy sector.

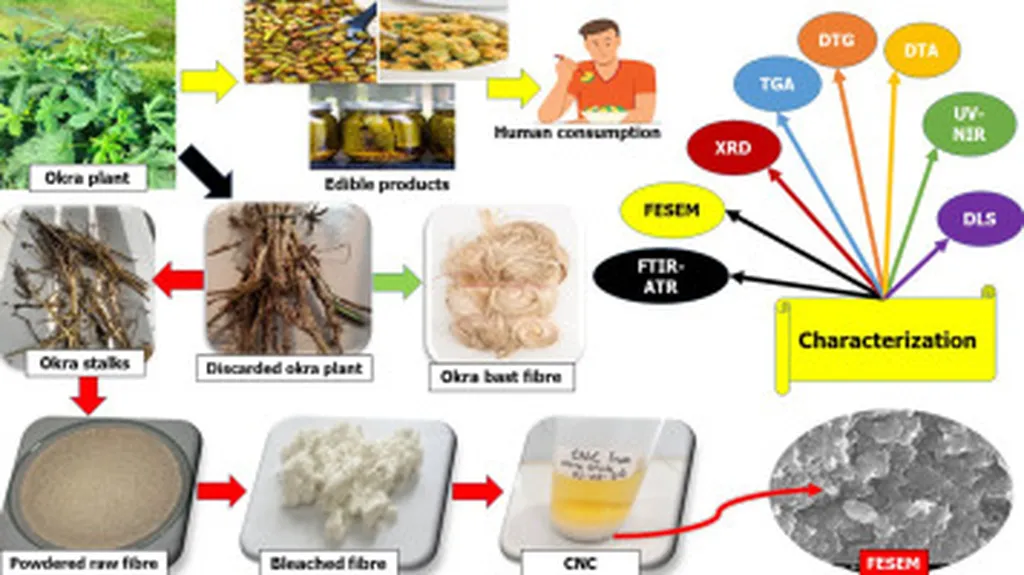

The study systematically evaluated the mechanical and thermal properties of composites made from AI and okra fibers, which are typically considered waste materials. By employing needle punch weaving and a hand layup process, the researchers fabricated composites with varying compositions of AI and okra fibers. The results were striking. “We found that a 35% fiber loading in nonwoven composites significantly enhanced the mechanical properties,” Mohanraj explained. This optimization led to notable improvements: a 4.75% increase in tensile strength, a 3.32% boost in flexural strength, a 4.23% rise in compressive strength, and a 6.57% enhancement in impact strength.

Among the composites tested, the H4 sample stood out, achieving the highest tensile strength (49.521 MPa) and flexural strength (72.523 MPa). This sample also exhibited peak compression strength and impact energy, thanks to the balanced fiber properties and efficient load transfer. The study underscores the potential of hybridizing AI and okra fibers to create eco-friendly, high-performance epoxy composites.

The implications for the energy sector are substantial. As the world shifts towards renewable energy sources, the demand for durable, lightweight, and sustainable materials is growing. Composites reinforced with AI and okra fibers could be used in wind turbine blades, solar panel frames, and other energy infrastructure components. “This research opens up new avenues for utilizing agricultural waste in high-value applications,” Mohanraj noted. “It’s a step towards a more sustainable future.”

The study’s findings highlight the importance of exploring unconventional materials for advanced applications. By leveraging the unique properties of AI and okra fibers, researchers have demonstrated that waste materials can be transformed into high-performance composites. This approach not only reduces environmental impact but also offers cost-effective solutions for various industries.

As the energy sector continues to evolve, the need for innovative materials will only grow. The research conducted by Mohanraj and his team provides a compelling case for the use of hybrid AI and okra fiber-reinforced composites. By pushing the boundaries of material science, they are shaping the future of sustainable energy infrastructure. The study, published in the Journal of Engineered Fibers and Fabrics, serves as a testament to the power of interdisciplinary research and the potential of waste materials in creating high-performance composites.