In a significant stride towards making fuel cell technology more commercially viable, researchers have developed a novel electrocatalyst that challenges the dominance of expensive platinum-based catalysts. The study, led by Nattawan Pitipuech from the Faculty of Engineering and Technology at King Mongkut’s University of Technology North Bangkok, introduces an ultra-durable and superior oxygen reduction reaction (ORR) electrocatalyst derived from an iron-based nanostructure.

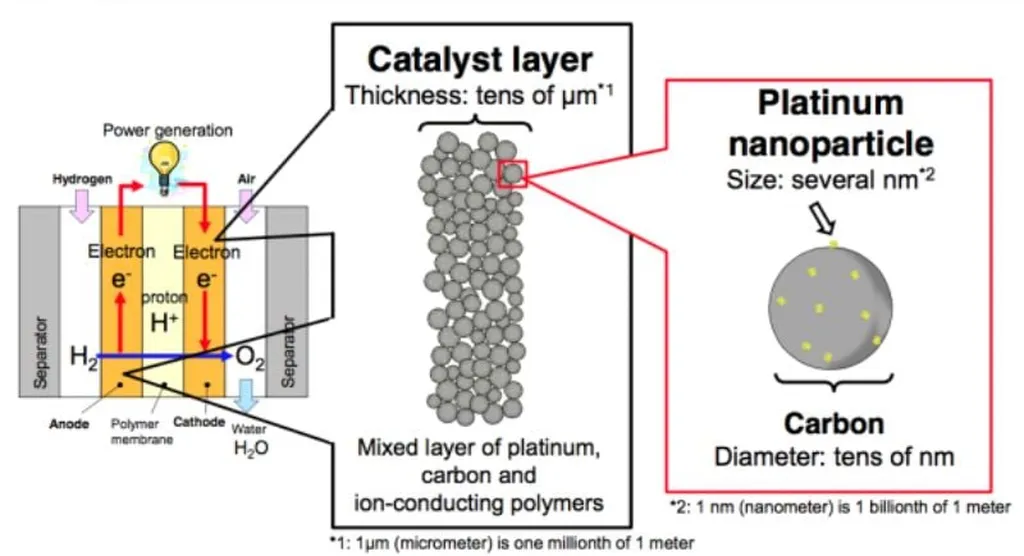

The research, published in *Discover Materials* (translated to English as *Exploring Materials*), addresses a critical hurdle in fuel cell commercialization: the high cost and poor stability of platinum nanoparticles supported on carbon (Pt/C) catalysts used in the cathode electrode. Pitipuech and her team have developed an alternative using an autogenic pressure-derived Fe/FeOx encapsulated iron-coordinated nitrogen-doped carbon (FeNC) nanostructure.

The team achieved this by calcining a solid mixture of oxidized carbon nanoparticles, melamine, and iron (II) acetate at varying temperatures (700°C, 800°C, and 900°C) under autogenic pressure. The FeNC sample heated at 700°C (FeNC700) demonstrated the best ORR performance, with an onset potential (Eonset) of 1.04 V and a half-wave potential (E1/2) of 0.89 V vs. the reversible hydrogen electrode (RHE). In comparison, the benchmark Pt/C electrocatalyst delivered an Eonset of 1.04 V vs. RHE but a lower E1/2 of 0.86 V vs. RHE.

Pitipuech explained, “The FeNC catalyst promotes the ORR process via a direct 4-electron transfer route, accompanied by an extremely low number of intermediate substances. This efficiency, coupled with its durability, makes it a promising candidate for commercial applications.”

The team investigated the microstructure, phase, surface area, and Fe-Nx active sites to understand the outstanding ORR performance of the synthesized catalysts. They found that the FeNC sample with a larger content of Fe-Nx active sites, coupled with the presence of Fe/FeOx encapsulated graphitic Fe-Nx doped carbon structure, resulted in remarkably high ORR performance under alkaline media.

Moreover, the FeNC700 sample exhibited excellent resistance to methanol poisoning and negligible ORR degradation against accelerated durability tests for 5,000 cycles. This durability is a significant advantage over traditional Pt/C catalysts, which often suffer from degradation and poisoning issues.

The implications for the energy sector are substantial. Fuel cells are a critical component in the transition to clean energy, offering efficient and zero-emission power generation. However, the high cost and limited durability of Pt/C catalysts have been major barriers to widespread adoption. The development of ultra-durable and superior ORR electrocatalysts like FeNC could significantly reduce costs and improve the longevity of fuel cells, making them more attractive for commercial use.

Pitipuech’s research opens new avenues for exploring carbon-based electrocatalysts and Fe-Nx active sites, potentially leading to further innovations in the field. As the energy sector continues to evolve, such advancements are crucial for achieving sustainable and efficient energy solutions.

The study, published in *Discover Materials*, highlights the potential of FeNC catalysts to revolutionize fuel cell technology, paving the way for a cleaner and more energy-efficient future.