In the quest to enhance the longevity and performance of asphalt pavements, researchers have turned to polymer modifications, and a recent study published in *Case Studies in Construction Materials* (translated from Persian as *Case Studies in Building Materials*) offers promising insights. Led by Abbas Nilforoushan from the Department of Civil Engineering at the Islamic Azad University in Amol, Iran, the research delves into the effectiveness of maleic anhydride-grafted polymers in improving bitumen properties and, consequently, the performance of Stone Mastic Asphalt (SMA) mixtures.

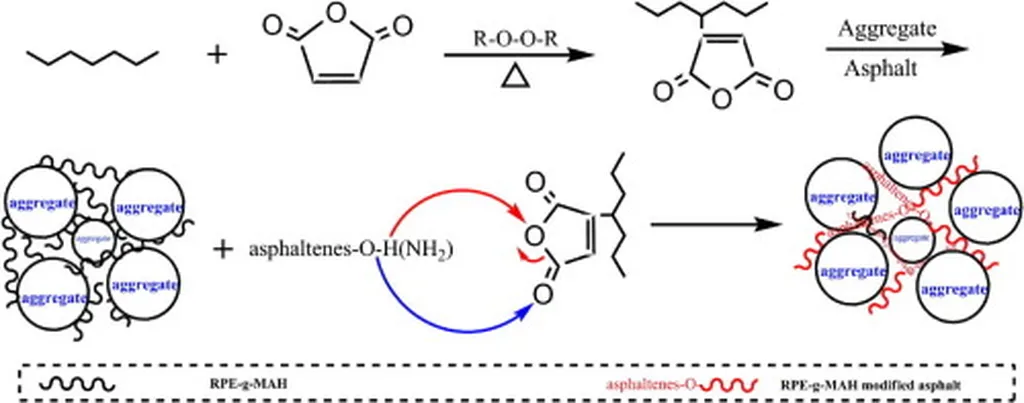

The study focuses on four polymers: polypropylene (PP), linear low-density polyethylene (LLDPE), maleic anhydride-grafted polypropylene (MAH-g-PP), and maleic anhydride-grafted linear low-density polyethylene (MAH-g-LLDPE). These polymers were incorporated into base bitumen at varying dosages (0%, 3%, 5%, and 7% by weight) to evaluate their impact on both binder and mixture performance.

Nilforoushan and his team conducted a comprehensive evaluation, including penetration, softening point, rotational viscosity, phase separation, and elastic recovery tests for the binders. For the SMA mixtures, they assessed resilient modulus, Hamburg wheel tracking, four-point bending fatigue, tensile strength ratio (TSR), and the Illinois Flexibility Index (FI) tests. The results were analyzed using statistical methods such as ANOVA and Pearson correlation in SPSS.

The findings revealed that grafted polymers, particularly MAH-g-LLDPE, significantly outperformed conventional polymers. “The mixture containing 7% MAH-g-LLDPE exhibited the highest elastic recovery (38.9%), the lowest phase separation, the highest TSR value (87.6%), a 154% increase in the flexibility index, and a 21.4% improvement in fatigue life compared to the control,” Nilforoushan explained. This suggests that MAH-g-LLDPE could be a game-changer in the construction industry, offering enhanced durability and performance for asphalt pavements.

The statistical analysis also highlighted the significant effects of the type, content, and structure of the polymer on both binder and mixture performance. Moreover, strong correlations were observed between certain binder properties and asphalt mixture performance indices, underscoring the importance of appropriate polymer selection in designing sustainable and high-performance asphalt mixtures.

The implications of this research are substantial for the energy sector, particularly in the production and application of polymer-modified bitumen. As the demand for more durable and sustainable infrastructure grows, the use of maleic anhydride-grafted polymers could become a standard practice, leading to longer-lasting roads and reduced maintenance costs. This could also drive innovation in the polymer industry, as companies seek to develop new, more effective modifiers for bitumen.

As Nilforoushan’s research demonstrates, the future of asphalt pavements lies in the strategic use of advanced materials. By leveraging the unique properties of maleic anhydride-grafted polymers, the construction industry can achieve significant improvements in performance and sustainability. This study, published in *Case Studies in Construction Materials*, serves as a crucial step forward in this ongoing quest for innovation and excellence.