In a significant stride towards enhancing the performance of metal matrix composites, researchers have drawn inspiration from nature to create a novel copper-based material that simultaneously boosts strength and ductility. This breakthrough, led by Shanquan Deng from the Electric Power Research Institute of Guangxi Power Grid Co., Ltd in Nanning, China, could have profound implications for the energy sector and beyond.

The study, published in *Materials Letters: X* (which translates to *Materials Letters: New*), addresses a longstanding challenge in materials science: the trade-off between strength and toughness in metal matrix composites. Traditionally, as strength increases, ductility and toughness tend to decrease, limiting the material’s overall performance and applicability.

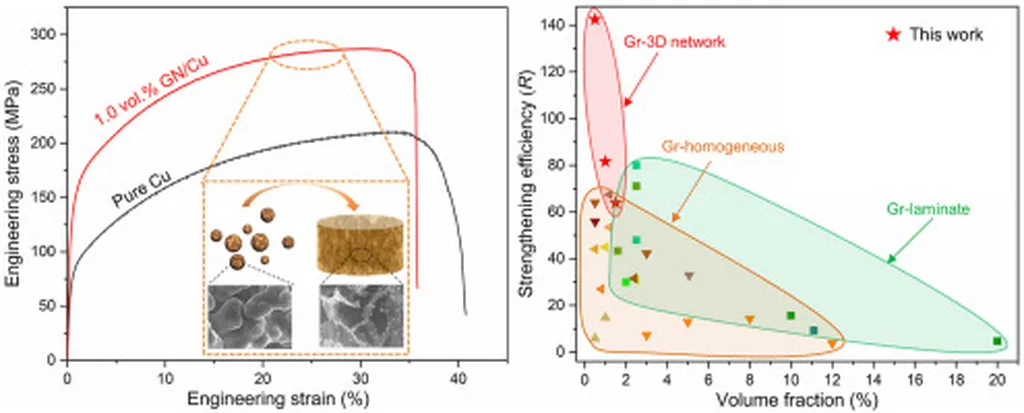

Deng and his team tackled this issue by designing a heterogeneous architecture, mimicking the complex structures found in biological materials. They created a composite consisting of a coarse-grained copper foam interpenetrated with ultrafine-grained graphene-copper (Gr-Cu) regions. This unique structure was fabricated using a mixing and hot-pressing sintering process.

The key to this innovation lies in the interplay between the different grain sizes. During tensile deformation, the strain gradient introduced by the hetero-deformation between the coarse-grained copper foam and the ultrafine-grained Gr-Cu microregions enhances the material’s ability to store dislocations, which are line defects in the crystal structure of the material that significantly influence its mechanical properties. Additionally, the coarse-grained regions act to mitigate stress concentration, blunting and deflecting crack propagation.

The results are impressive. The tensile strength of the sintered heterostructure composite reached 347.5 MPa, with an elongation of 7%, representing a 54% and 45% improvement over the Gr-Cu composite, respectively. “This synergistic enhancement of strength and toughness opens up new possibilities for the use of metal matrix composites in demanding applications,” Deng noted.

The potential commercial impacts for the energy sector are substantial. The enhanced mechanical properties of this composite could lead to more robust and efficient components in power generation and transmission systems. For instance, the improved strength and toughness could enhance the performance of electrical contacts, switchgear components, and other critical parts subjected to high mechanical and electrical stresses.

Moreover, the innovative approach demonstrated in this study could inspire further research into heterogeneous architectures in other materials. As Deng pointed out, “The principles underlying this design could be applied to a wide range of materials, paving the way for the development of advanced composites with tailored properties.”

This research not only advances our understanding of material science but also highlights the potential of bio-inspired designs in creating high-performance materials. As the energy sector continues to evolve, such innovations will be crucial in meeting the demands for more efficient, reliable, and sustainable technologies. The study published in *Materials Letters: X* serves as a testament to the power of interdisciplinary research and the endless possibilities that lie at the intersection of biology and materials science.