In the bustling heart of Beijing, within the walls of the Key Laboratory of Special Equipment Safety and Energy-Saving for State Market Regulation, a groundbreaking approach to machine defect identification is taking shape. Led by L. Hou of the China Special Equipment Inspection & Research Institute, a novel method is being developed that could revolutionize how we detect bearing defects, with significant implications for the energy sector.

Traditional methods of identifying machine defects have long been plagued by issues of poor adaptability and low accuracy. While artificial intelligence has offered some improvements, these methods often focus solely on neural networks, overlooking the intricate connections and influences of data nodes. Hou and his team are changing that narrative.

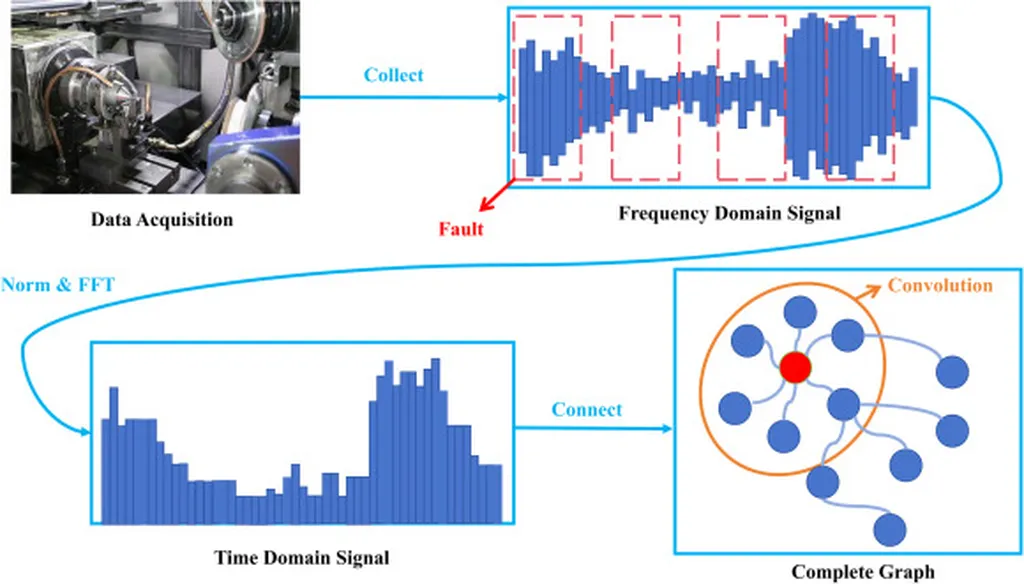

Their research, published in the journal *Mechanical Sciences* (which translates to *机械科学* in Chinese), introduces a feature-enhanced method based on a data dynamic network. This approach preprocesses data using optimization algorithms and defines nodes and edges to construct a comprehensive data dynamic network. But the innovation doesn’t stop there. The team also employs energy analysis, coupling it with the data dynamic network to enhance feature identification.

“This method not only improves the accuracy of defect identification but also provides a more holistic understanding of the data,” Hou explains. “By considering the connections and influences of data nodes, we can achieve a more robust and adaptable system.”

The implications for the energy sector are profound. Bearings are critical components in various energy systems, from wind turbines to industrial machinery. Early and accurate identification of bearing defects can prevent costly downtime and catastrophic failures, ensuring the smooth and efficient operation of energy infrastructure.

Hou’s method defines training sets and test sets using different data coupling techniques, allowing for a more thorough evaluation of the proposed method. The performance evaluation, conducted through an evaluation function, promises more effective detection of bearing defects, ultimately leading to improved safety and efficiency in energy systems.

As the energy sector continues to evolve, the need for advanced diagnostic tools becomes ever more pressing. Hou’s research offers a glimpse into the future of machine defect identification, where data dynamic networks and energy analysis work in tandem to provide unparalleled accuracy and adaptability.

“This is just the beginning,” Hou notes. “The potential applications of this method extend far beyond bearing defect identification. We are excited to explore how this approach can be applied to other areas of machine learning and data analysis.”

In a field where precision and reliability are paramount, Hou’s work stands as a testament to the power of innovative thinking and cutting-edge technology. As the energy sector continues to push the boundaries of what’s possible, this research could very well shape the future of machine defect identification, ensuring safer, more efficient, and more reliable energy systems for all.