In the world of construction and infrastructure, the integrity of materials is paramount, especially when it comes to structures that support critical energy sector projects. A recent study published in the journal *Case Studies in Construction Materials* (translated from Chinese as “典型建筑材料研究”) sheds new light on the durability of cantilever anti-slip piles, a crucial component in many construction projects. The research, led by Yanping Jia from the School of Civil Engineering at Chongqing Jiaotong University and the State Key Laboratory of Mountain Bridge and Tunnel Engineering, delves into the complex interplay of steel bar corrosion, rust expansion, and the subsequent cracking of protective layers.

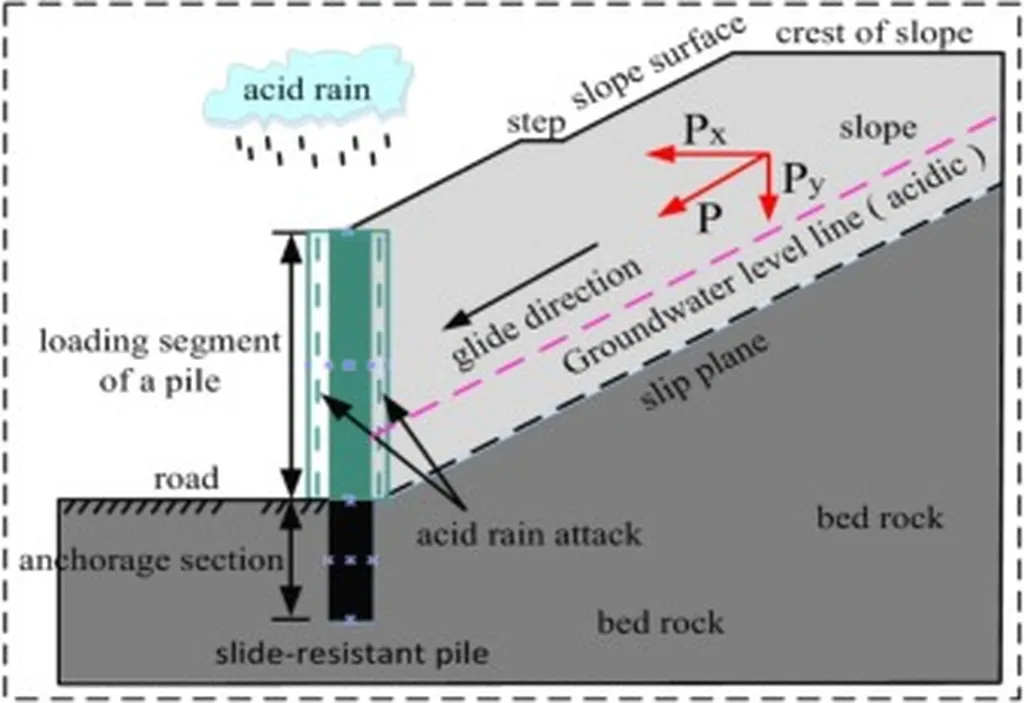

Cantilever anti-slip piles are widely used in various construction scenarios, particularly in the energy sector, where they provide essential support for pipelines, transmission towers, and other critical infrastructure. However, the corrosion of steel bars within these piles has long been a concern, leading to structural degradation and potential failures. Jia’s research aims to address this issue by developing a predictive model that can anticipate the timing of rust expansion and the resulting cracking of the protective layer.

The study employs the theory of elastic mechanics and the mechanism of steel bar rust expansion to establish an analysis model. This model examines the initial rust cracking at the rebar-concrete interface and the partial cracking of the protective layer. “The synergistic mechanism of rust, load, and stirrup restraint is crucial in understanding the overall behavior of the pile,” explains Jia. By analyzing these factors, the research team developed a prediction model that can estimate the rust expansion and cracking time of the protective layer surface.

One of the key findings of the study is the relative influence of different factors on the critical corrosion depth. The research reveals that the external load has a greater impact than the filling effect of the corrosion products and the binding effect of the stirrups. This insight is particularly relevant for the energy sector, where structures are often subjected to significant loads and environmental stresses. “The closer to the reinforcing bars of the pile body, the more severe the damage,” notes Jia, highlighting the importance of regular inspections and maintenance.

The accuracy of the prediction model was verified by comparing it with the results of examples and other models, ensuring its reliability and applicability. This model can be a game-changer for the energy sector, allowing engineers to predict and mitigate potential failures before they occur. By understanding the timing and extent of rust expansion and cracking, construction professionals can implement preventive measures, such as targeted maintenance and the use of corrosion-resistant materials, to extend the lifespan of critical infrastructure.

The implications of this research are far-reaching. For the energy sector, it offers a tool to enhance the durability and safety of structures, reducing the risk of costly repairs and downtime. For the construction industry as a whole, it provides a deeper understanding of the factors influencing material degradation, paving the way for more resilient and long-lasting designs.

As the energy sector continues to expand and evolve, the need for robust and reliable infrastructure becomes ever more critical. Yanping Jia’s research offers a valuable contribution to this field, providing insights and tools that can shape future developments and ensure the integrity of critical structures. By leveraging the findings of this study, construction professionals can build a more sustainable and resilient future for the energy sector and beyond.