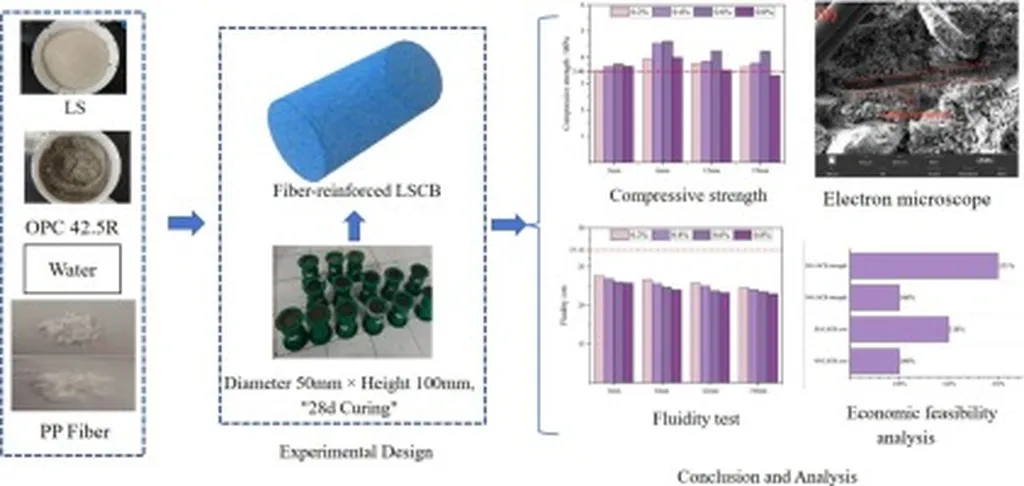

In the quest to transform industrial waste into valuable construction materials, researchers have made a significant stride that could reshape the future of mine backfilling and beyond. A recent study published in *Materials & Design* (also known as *材料与设计*) explores how polypropylene (PP) fibers can enhance the properties of lithium slag cement backfill (LSCB), offering a promising solution for the energy sector and construction industry.

Ling Hu, a researcher from the Division of Urban Construction Engineering at Wenhua College in Wuhan, China, led the investigation into the influence of PP fiber content and length on LSCB. The study is particularly relevant as it addresses the dual challenge of improving the engineering performance of mine backfill bodies while promoting the resource utilization of industrial solid waste.

The research revealed that increasing the content and length of PP fibers reduces the fluidity of the slurry, which is a critical factor in the practical application of backfill materials. However, the real breakthrough came from the uniaxial compression tests. “We found that fiber-reinforced samples exhibited similar stress–strain behaviors, but the length of the fibers played a crucial role,” Hu explained. Shorter fibers enhanced initial strength but offered limited resistance to large deformations. Interestingly, medium-length fibers (6 mm and 12 mm) showed a more significant reinforcing effect compared to both short (3 mm) and long (19 mm) fibers.

The optimal balance was struck when the PP fiber content was 0.6% and the length was 6 mm. Under these conditions, the 28-day compressive strength of LSCB reached an impressive 4.53 MPa, a 31% increase over the blank group. This enhancement can be attributed to the skeletal structure provided by the PP fibers within the hydration gels, as well as the adhesion, friction, and cohesion between the fibers and the matrix, which help resist crack propagation.

The economic feasibility analysis conducted as part of the study concluded that adding 0.6% of 6 mm PP fibers is a viable option for engineering applications. This finding is particularly significant for the energy sector, where the efficient and cost-effective use of materials is paramount.

The implications of this research extend beyond mine backfilling. The enhanced mechanical properties and improved resource utilization offered by PP fiber-reinforced LSCB could open new avenues for sustainable construction practices. As the energy sector continues to seek innovative solutions for waste management and material efficiency, this study provides a compelling case for the adoption of fiber-reinforced cement backfill.

Hu’s work not only highlights the potential of industrial waste as a valuable resource but also underscores the importance of optimizing material properties for practical applications. As the construction and energy sectors continue to evolve, the insights gained from this research could pave the way for more sustainable and efficient practices, ultimately benefiting both the industry and the environment.