In the relentless pursuit of advanced materials for the energy sector, a recent study published in *Cailiao gongcheng* (translated to *Materials Engineering*) has shed light on the critical interplay between hygrothermal aging and the mechanical properties of polymer matrix composites. Led by WANG Xiang from the Beijing Key Laboratory of Aeronautical Materials Testing and Evaluation at AECC Beijing Institute of Aeronautical Materials, the research delves into the behavior of T700/BP9916 composites, a material increasingly relevant to the energy sector due to its potential applications in wind turbines and other high-performance environments.

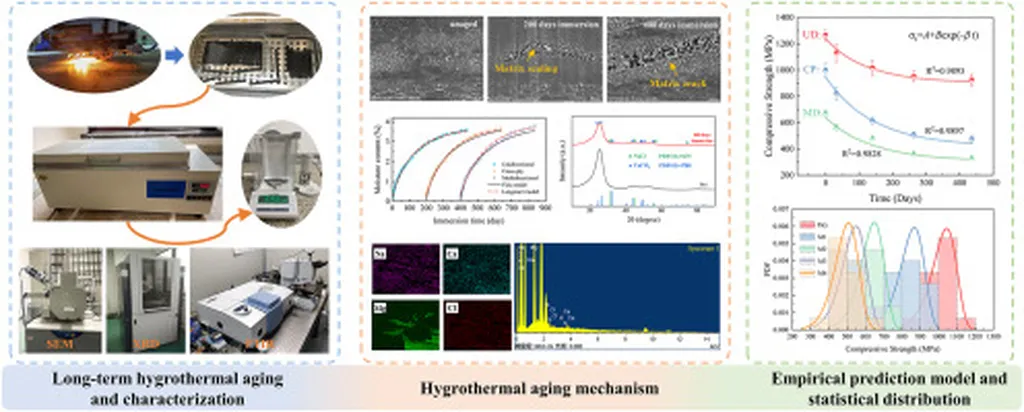

The study focuses on the hygrothermal aging tests and compression tests conducted on T700/BP9916 composites plates with open-holes, a common structural feature in many energy sector applications. The results reveal that the moisture absorption of these composites follows typical Fick diffusion behavior, a finding that underscores the importance of understanding and mitigating the effects of environmental exposure on material performance.

“Our findings indicate that the maximum load of the open-hole compression (OHC) strength decreases by approximately 5.2% after hygrothermal aging,” WANG Xiang explained. “This reduction, while significant, is primarily due to the moisture absorption rather than the internal stress caused by hygrothermal aging, which we found to be minimal.”

The research also employed ABAQUS software to simulate the residual stress distribution in the specimens after hygrothermal aging. The simulations, which considered the hygrothermal expansion behavior and the linear relationship between mechanical properties and moisture absorption, provided valuable insights into the material’s performance under real-world conditions.

“Our simulations showed a good agreement with the experimental data, with a relative error of only 0.88% in the maximum load of OHC tests without hygrothermal aging,” WANG Xiang noted. “However, the error increased to 6.21% during the hygrothermal environment, highlighting the complexity of accurately modeling the hygrothermal effects on material properties.”

The study’s findings have significant implications for the energy sector, where the reliability and longevity of materials are paramount. By understanding the impact of hygrothermal aging on the mechanical properties of composites, engineers can design more robust and durable structures, ultimately leading to safer and more efficient energy systems.

As the energy sector continues to evolve, the insights gained from this research could pave the way for the development of advanced materials that can withstand the rigors of environmental exposure. “This research is a stepping stone towards creating more resilient materials for the energy sector,” WANG Xiang concluded. “It underscores the need for continued investigation into the hygrothermal effects on composites and the development of more accurate simulation models.”

Published in *Cailiao gongcheng*, this study not only advances our understanding of material behavior but also sets the stage for future innovations in the energy sector. As the world moves towards more sustainable and efficient energy solutions, the role of advanced materials will be more critical than ever, and research like this is at the forefront of that charge.