In a breakthrough that could significantly enhance the accuracy and reliability of underground construction monitoring, researchers at the China University of Mining and Technology (Beijing) have developed a novel method for creating high-quality speckle patterns in transparent soil testing. This innovation, known as the High Contrast Particle Staining (HCPS) method, promises to revolutionize the way engineers and scientists observe and measure soil deformation during construction projects, particularly in the energy sector.

The research, led by Dr. Li Gengzhao and his team, addresses a critical challenge in the joint application of transparent soil testing technology and digital image correlation technology. “The quality stability of speckle patterns directly determines image acquisition and measurement accuracy,” explains Dr. Li. “Our HCPS method ensures stable, high-quality patterns, which are essential for precise measurements.”

The team’s findings, published in the journal *Yantu gongcheng xuebao* (translated to *Rock and Soil Mechanics*), reveal that the optimal staining agents for transparent soil are black water-based chromatin solution and white water-based matte paint, with an optimal configuration ratio of 8:10. This ratio maximizes the measurement image gradient (MIG), resulting in the flattest strain nephograms and the least identification error of speckle over-range.

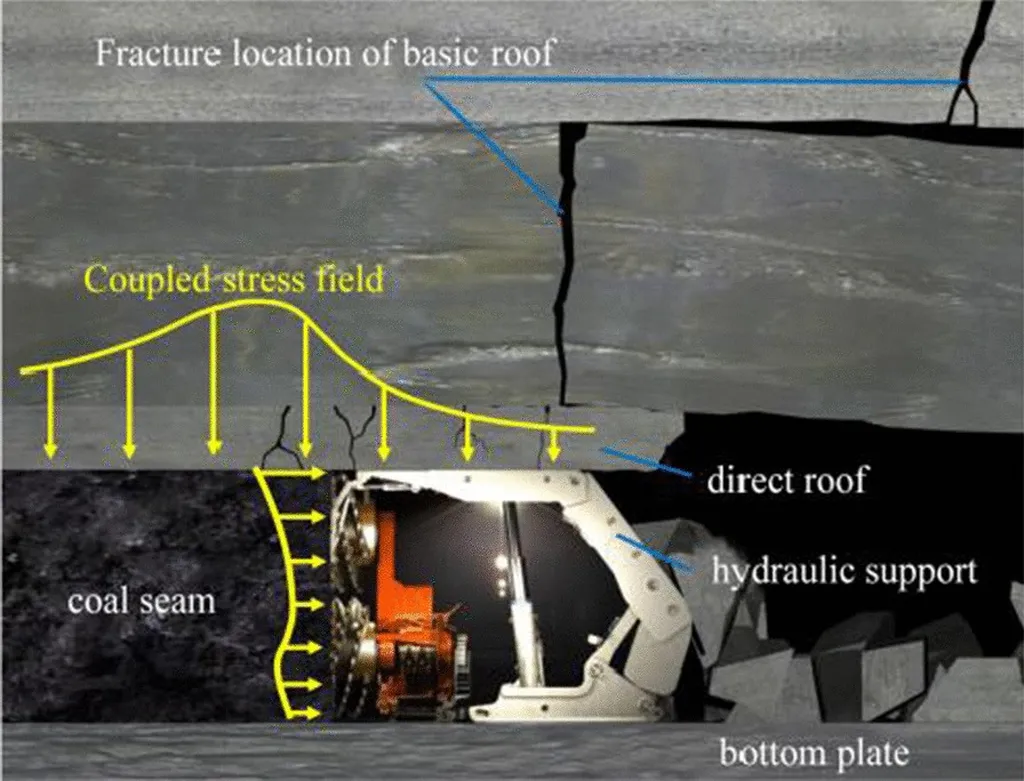

The practical implications of this research are substantial, particularly for projects involving rectangular pipe-jacking, a technique commonly used in the energy sector for installing pipelines and conduits underground. “Our transparent soil model test and field monitoring data jointly revealed the occurrence of the back-soil effect of rectangular pipe-jacking,” says Dr. Li. “This effect includes subside area, compensation area, and uplift area gradually appearing along the jacking direction, and it is continuous in long-distance projects.”

The research also sheds light on the causes of regional uplift deformation. “The uplift of the subside area and compensation area is caused by jacking pressure, while the uplift area is influenced by both jacking pressure and pipe-soil friction,” explains Dr. Li. “The regional uplift deformation caused by pipe-soil friction is twice that caused by jacking pressure.”

The HCPS method’s ability to avoid problems of overexposure, distortion, interference, and lack of information makes it a valuable tool for engineers and researchers. “This method has achieved a good experimental application effect,” says Dr. Li. “It provides a reliable way to monitor and measure soil deformation, which is crucial for the safety and efficiency of underground construction projects.”

The commercial impacts of this research are far-reaching. By improving the accuracy of soil deformation measurements, the HCPS method can enhance the safety and efficiency of underground construction projects, reducing the risk of failures and delays. This is particularly important in the energy sector, where the installation of pipelines and conduits is a critical aspect of infrastructure development.

Moreover, the research’s findings on the back-soil effect and the causes of regional uplift deformation can inform the design and implementation of underground construction projects, leading to more effective and cost-efficient solutions.

As the energy sector continues to evolve, the demand for accurate and reliable monitoring techniques will only grow. The HCPS method developed by Dr. Li and his team represents a significant step forward in meeting this demand, paving the way for safer, more efficient, and more sustainable underground construction practices.