In the quest to enhance the performance of aluminum alloys, particularly for high-temperature applications, researchers have made a significant stride. A recent study published in the journal *Materials Research Express* (which translates to *Materials Research Express* in English) has uncovered how varying the ratio of zinc (Zn) to magnesium (Mg) in Al-6Cu alloys can dramatically improve their mechanical properties, especially at elevated temperatures. This research, led by Yu Xiong from the School of Resources, Environment and Materials at Guangxi University in China, could have profound implications for industries that rely on high-strength, heat-resistant materials, including the energy sector.

The study focused on the effect of different Zn/Mg ratios on the microstructure and mechanical properties of Al-6Cu alloys, both in their as-cast state and after heat treatment. The alloys were subjected to a T6 heat treatment, a process known to enhance the strength and durability of aluminum alloys. The researchers found that the optimal Zn/Mg ratio for maximizing the alloy’s performance was 1.5:0.5.

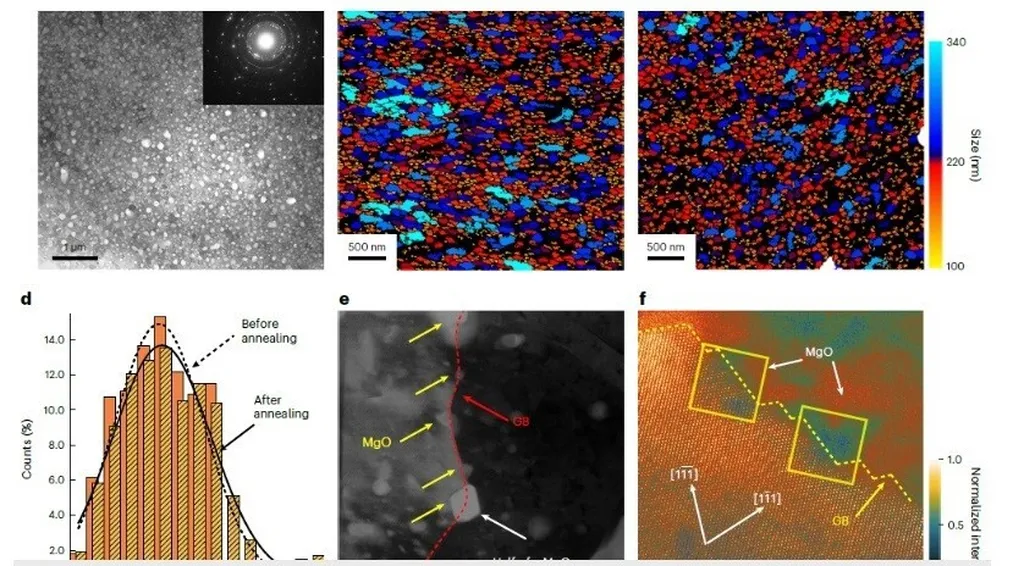

“This ratio led to the finest and most abundant precipitation of the θ’-Al₂Cu phase, which is crucial for the alloy’s strength,” explained Xiong. The θ’-Al₂Cu phase is a fine, dispersive precipitate that forms within the alloy’s matrix during heat treatment, significantly enhancing its mechanical properties.

The study revealed that the alloy with a Zn/Mg ratio of 1.5:0.5 exhibited the highest tensile strength at high temperatures, reaching 137.7 MPa. This is a remarkable 75.32% increase compared to the as-cast alloy. The improved performance is attributed to the formation of the maximum number of Zn-Mg co-clusters, which in turn promote the precipitation of the θ’ phase.

The implications of this research are substantial for industries that require materials capable of withstanding high temperatures and mechanical stress. In the energy sector, for instance, the development of more robust and heat-resistant alloys could lead to more efficient and durable components for power generation and transmission. This could include everything from turbine blades to high-voltage transmission lines, where materials are subjected to extreme conditions.

Moreover, the findings could pave the way for the development of new aluminum alloys tailored for specific applications. By fine-tuning the Zn/Mg ratio, manufacturers could produce alloys with enhanced properties for various industrial uses, from automotive to aerospace.

“This research opens up new possibilities for the design and optimization of aluminum alloys,” said Xiong. “It provides a roadmap for achieving superior mechanical properties through precise control of alloying elements and heat treatment processes.”

As the demand for high-performance materials continues to grow, particularly in the energy sector, the insights gained from this study could be instrumental in driving innovation and technological advancements. By understanding the intricate relationship between alloy composition, microstructure, and mechanical properties, researchers and engineers can push the boundaries of what is possible, ultimately leading to more efficient, reliable, and sustainable technologies.