In the quest to bolster the resilience and energy absorption of honeycomb structures, a team of researchers led by Daqian Zhang from the College of Aerospace Engineering at Shenyang Aerospace University in China has made significant strides. Their work, recently published in *Materials Research Express* (which translates to “Materials Research Express” in English), introduces two innovative designs that could revolutionize industries requiring robust, energy-absorbing materials, particularly in the energy sector.

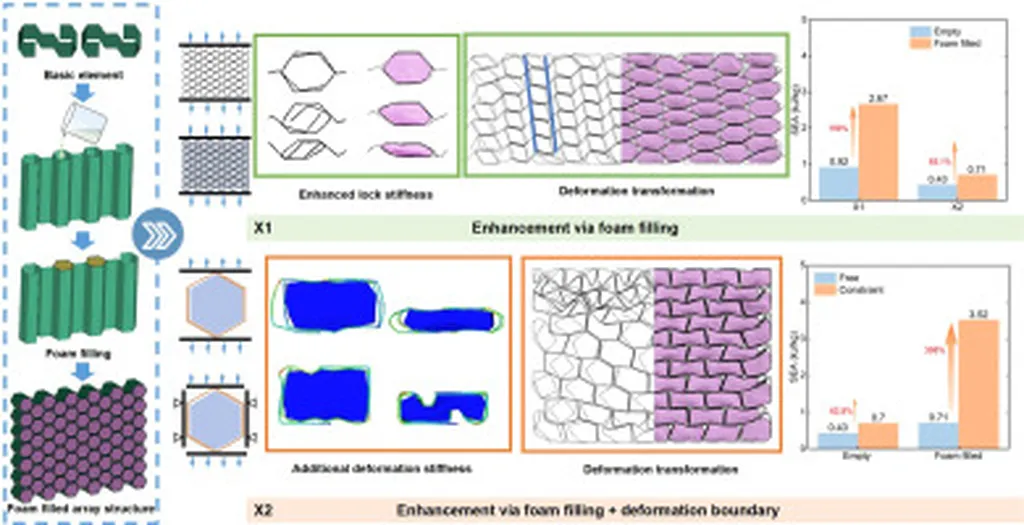

Honeycomb structures are widely used for their lightweight and strong properties, but their impact resistance and energy absorption capabilities have been areas needing improvement. Zhang and his team addressed this by developing two Improved Arc-Edged Concave Honeycomb (IAEC) structures, dubbed IAEC-I and IAEC-II. These designs incorporate a thin-walled cylindrical structure and replace the traditional horizontal wall with a double-crossed sloping wall, enhancing both impact resistance and energy absorption.

“The introduction of the circular thin-walled structure allows our IAEC honeycomb to retain the negative Poisson’s ratio effect of the traditional Arc-Edged Concave Honeycomb while significantly boosting its impact resistance and energy absorption efficiency,” Zhang explained. This means that under different impact velocities, the new designs exhibit superior performance compared to their predecessors.

The team’s findings are compelling. At various impact velocities, the average nominal stress and specific energy absorption of IAEC-I and IAEC-II surpassed those of the traditional Arc-Edged Concave Honeycomb. For instance, at an impact velocity of 3 meters per second, the platform nominal stress of IAEC-I increased by 66.8%, and its specific energy absorption rose by 56.1%. These improvements highlight the potential of these structures to withstand and absorb energy from high-impact events, making them ideal for applications in the energy sector where safety and durability are paramount.

The research also delves into the effects of impact velocity and relative density on the stress of the IAEC honeycomb platform, formulating an empirical prediction model for platform stress. This model could be instrumental in designing structures tailored to specific impact scenarios, ensuring optimal performance and safety.

Moreover, the study provides a comprehensive analysis of how geometric parameters influence the energy absorption characteristics of honeycomb structures. This insight could pave the way for more efficient and effective designs in various industries, from aerospace to automotive and beyond.

The implications of this research are far-reaching. For the energy sector, where structures often face high-impact events, the enhanced energy absorption and impact resistance of IAEC structures could lead to safer and more durable infrastructure. This could be particularly beneficial in offshore wind farms, where structures are subjected to harsh environmental conditions and need to absorb significant energy from waves and winds.

As the world continues to push the boundaries of material science, the work of Zhang and his team offers a promising avenue for innovation. Their findings not only advance our understanding of honeycomb structures but also open up new possibilities for their application in high-stress environments. With the energy sector increasingly focused on sustainability and resilience, the timing of this research couldn’t be more relevant.

In the words of Zhang, “Our research provides new ideas for the design and application of high-strength, high-energy-absorbing honeycomb structures.” As industries continue to evolve, the insights gained from this study could shape the future of material design, ensuring that our structures are not only stronger but also more capable of withstanding the challenges of tomorrow.