In the relentless pursuit of energy efficiency, researchers are pushing the boundaries of material science to enhance the performance of electrical steels, a critical component in transformers and generators. A recent study published in *Cailiao gongcheng* (which translates to *Materials Engineering*) explores how processing parameters influence the microstructure and texture of ultra-thin non-oriented electrical steel, offering promising insights for the energy sector.

Led by SHAN Zhongyu from the School of Materials Science and Engineering at the University of Science and Technology Beijing, the research focuses on the two-stage cold rolling method, a technique that has shown potential in optimizing the texture and magnetic properties of these steels. “The thinning of electrical steel is a clear trend in the industry,” explains SHAN, “but achieving the right balance between reduction rates and surface effects is crucial for maintaining superior magnetic properties.”

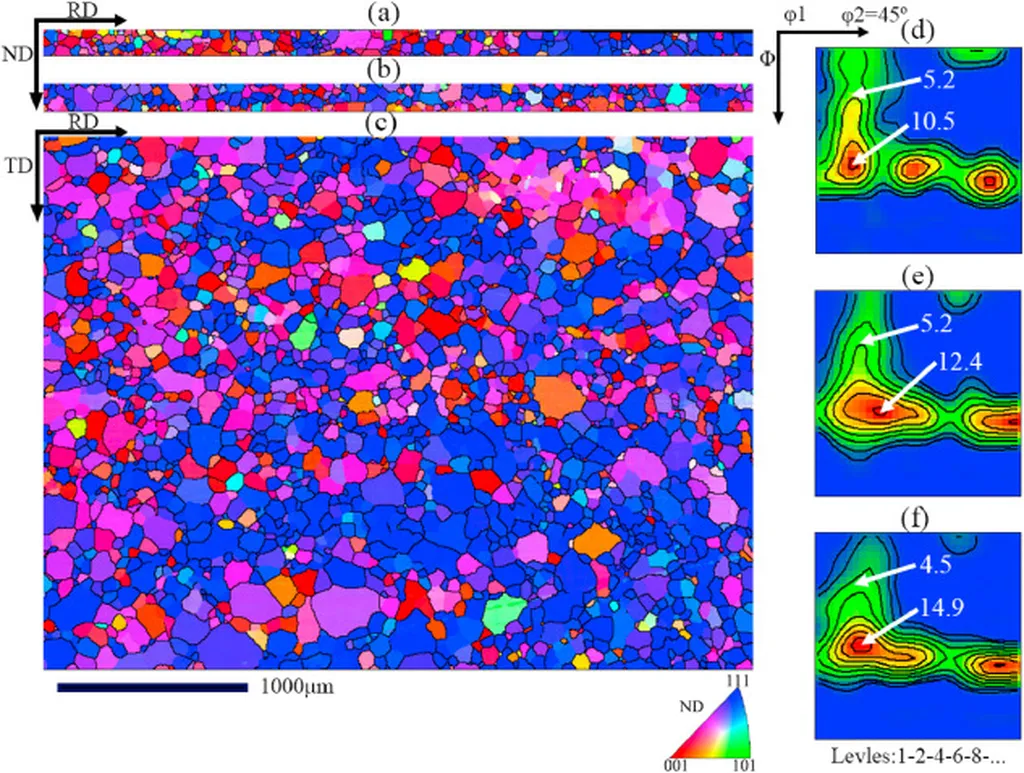

The study reveals that when the combined reduction from two cold rolling stages falls within the range of approximately 75% to 81%, the resulting texture and magnetic properties are significantly better than those achieved with more extreme reduction combinations. This finding is particularly relevant for manufacturers aiming to produce high-performance, ultra-thin electrical steels.

One of the most intriguing aspects of the research is the examination of the surface effect during prolonged holding. The study found that grain growth is significantly hindered in thinner sheets, with the average grain size of a 0.1 mm thick sample failing to exceed the sheet thickness after 60 minutes of annealing at 920°C. In contrast, a thicker 0.27 mm sample showed substantial grain growth, reaching an average size of 175 μm under the same conditions.

“The surface effect plays a pivotal role in grain growth, especially in ultra-thin sheets,” notes SHAN. “Understanding and controlling this effect can lead to significant improvements in the magnetic properties of electrical steels, which is vital for enhancing the efficiency of energy systems.”

The implications of this research are far-reaching for the energy sector. As the demand for more efficient and compact electrical devices grows, the development of ultra-thin non-oriented electrical steels with optimized magnetic properties becomes increasingly important. By fine-tuning the processing parameters, manufacturers can produce steels that reduce energy losses in transformers and generators, contributing to a more sustainable energy infrastructure.

SHAN’s work not only sheds light on the intricate relationship between processing parameters and material properties but also paves the way for future advancements in the field. As the energy sector continues to evolve, the insights gained from this research will be instrumental in driving innovation and improving the performance of electrical steels.

For professionals in the energy and materials science fields, this study serves as a reminder of the critical role that material engineering plays in shaping the future of energy efficiency. By delving into the nuances of texture and microstructure, researchers like SHAN Zhongyu are helping to build a foundation for the next generation of high-performance electrical steels.