In the realm of materials science, understanding the behavior of metals under stress is crucial for advancing various industries, including energy. A recent study published in the Archives of Mechanics (Archiwum Mechaniki Stosowanej), led by M. Mucha from the Chair for Computational Engineering at the Cracow University of Technology, delves into the fascinating world of aluminum alloy AW5083, shedding light on phenomena that could revolutionize how we approach material design and application.

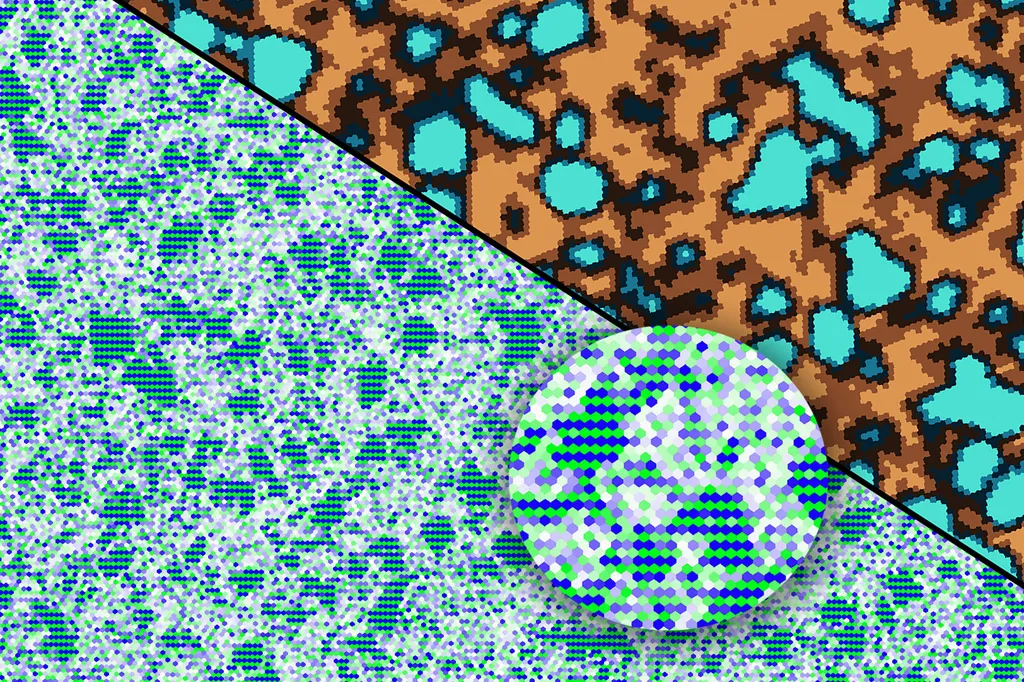

The research focuses on two key phenomena: Lueders bands and the Portevin–Le Chatelier (PLC) effect. Lueders bands are localized deformation zones that propagate through a material under stress, while the PLC effect manifests as serrations in the stress-strain curve, indicative of dynamic strain aging. These instabilities are not just academic curiosities; they have significant implications for the durability and performance of materials in real-world applications.

Mucha and his team conducted a series of experiments on bone-shaped samples of aluminum alloy AW5083 at room temperature, subjecting them to different loading rates. The results were striking, revealing the intricate dance of instabilities and eventual failure. “The experiments showed a complex interplay between the material’s microstructure and its mechanical response,” Mucha explained. “Understanding this interplay is crucial for predicting and mitigating failure in practical applications.”

To complement the experimental work, the researchers developed a large strain thermovisco-plasticity model. This model incorporates initial softening and a hardening function based on the Estrin–McCormick concept, which helps represent the serrations and traveling shear bands observed in the experiments. The model’s predictive capabilities were thoroughly examined, and the results were promising. “The simulations not only reproduced the Lueders bands and the PLC effect but also showed good agreement with the experimental force-displacement diagrams and temperature levels,” Mucha noted.

The implications of this research are far-reaching, particularly for the energy sector. Aluminum alloys are widely used in energy infrastructure, from pipelines to renewable energy technologies. Understanding and controlling the instabilities in these materials can lead to more robust and efficient designs. For instance, in the oil and gas industry, pipelines are subjected to varying loads and temperatures, making them susceptible to failure if the material behavior is not well understood. Similarly, in renewable energy applications, such as wind turbines, the materials must withstand dynamic loading conditions without compromising performance.

The ability to predict and model these instabilities opens the door to innovative solutions. Engineers can design materials and structures that are more resistant to failure, leading to safer and more reliable energy infrastructure. Additionally, the insights gained from this research can inform the development of new alloys with improved properties, tailored for specific applications.

As the energy sector continues to evolve, the demand for advanced materials that can withstand extreme conditions will only grow. The work of Mucha and his team represents a significant step forward in this direction. By bridging the gap between experimental observations and theoretical models, they have provided a powerful tool for the future of materials science.

In the words of Mucha, “This research is not just about understanding the past behavior of materials but about shaping the future of material design.” As we look ahead, the insights from this study will undoubtedly play a pivotal role in advancing the energy sector and beyond.