In the realm of advanced materials and manufacturing, a groundbreaking study has emerged that could significantly impact the energy sector’s pursuit of high-performance composite materials. Published in the journal *Materials Research Express* (translated to English as “Materials Research Express”), the research introduces a novel numerical model designed to simulate the impregnation of fibrous media with particle-filled resins, specifically tailored for the vacuum-assisted resin infusion (VARI) process.

At the helm of this innovative research is Houssem Cherif, a researcher affiliated with the Laboratory of Mechanics, Modeling and Production at the National Engineering School of Sfax in Tunisia, as well as the Laboratory of Mechanics of Normandy in France. Cherif’s work focuses on a process that is increasingly vital for producing complex, fiber-reinforced structures with minimal tooling and pressure.

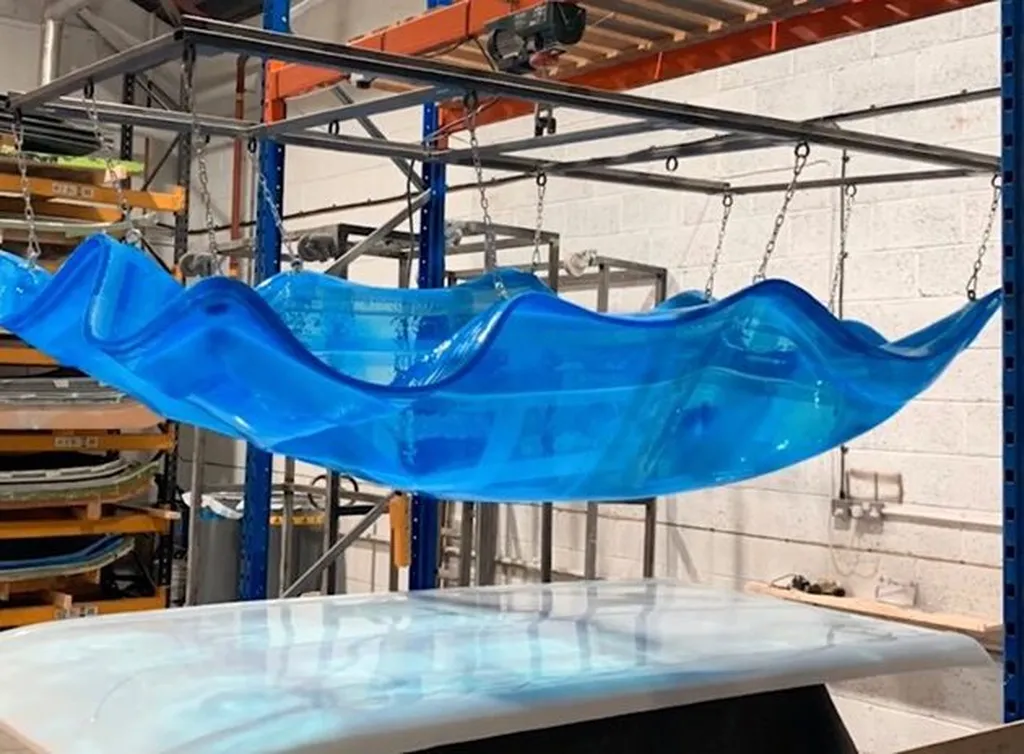

“Resin infusion processes are essential in manufacturing high-performance composite materials, providing a cost-effective and scalable method for producing complex fibre-reinforced structures,” Cherif explains. “Among these, vacuum-assisted resin infusion (VARI) is especially valued for its ability to produce void-free laminates with minimal tooling and pressure.”

The study introduces a numerical model designed to simulate the impregnation of a fibrous medium with a particle-filled resin, specifically tailored to the VARI process under atmospheric pressure. This infusion method has not been extensively explored in the literature, particularly with regard to suspended particles. The model aims to accurately replicate mold filling behavior, considering both suspension flow dynamics and particle retention mechanisms.

Validation of the model was performed using both analytical and numerical benchmarks, producing consistent and reliable results. An advanced parametric study was conducted to evaluate how key process parameters such as initial concentration, vacuum pressure, and fiber volume fraction affect the dispersion of particles during infusion.

“Our results demonstrate that the final particle distribution within the composite strongly depends on the initial concentration, the travel distance of the flow front, and the fibre volume fraction relative to the cavity geometry,” Cherif notes. “This provides valuable insights for the precise control of reinforcement architecture in functional composite manufacturing.”

The implications of this research are profound for the energy sector, where high-performance composite materials are increasingly in demand. From wind turbine blades to offshore structures, the ability to precisely control the distribution of particles within composite materials can enhance strength, durability, and functionality.

As the energy sector continues to push the boundaries of material performance, Cherif’s research offers a promising avenue for innovation. By providing a deeper understanding of the VARI process and its unique flow behavior, this study paves the way for more efficient and effective manufacturing of advanced composite materials.

In the words of Cherif, “This research not only advances our understanding of the VARI process but also opens up new possibilities for the design and manufacture of functional composites tailored to specific applications in the energy sector.”

As the energy sector continues to evolve, the insights gained from this research could shape future developments in the field, driving innovation and enhancing the performance of composite materials in critical applications.