In the high-stakes world of aerospace and energy infrastructure, where composite materials are the backbone of modern design, a new study is making waves by tackling one of the industry’s most persistent challenges: delamination. Rohan Nandkishor Soman, a researcher at the Institute of Fluid-Flow Machinery, Polish Academy of Sciences in Gdańsk, has published groundbreaking work in the journal *Computer Assisted Methods in Engineering and Science* (translated to English as *Computational Methods in Engineering and Science*), offering a fresh perspective on how to model and mitigate delamination in composite shells under varying temperature conditions.

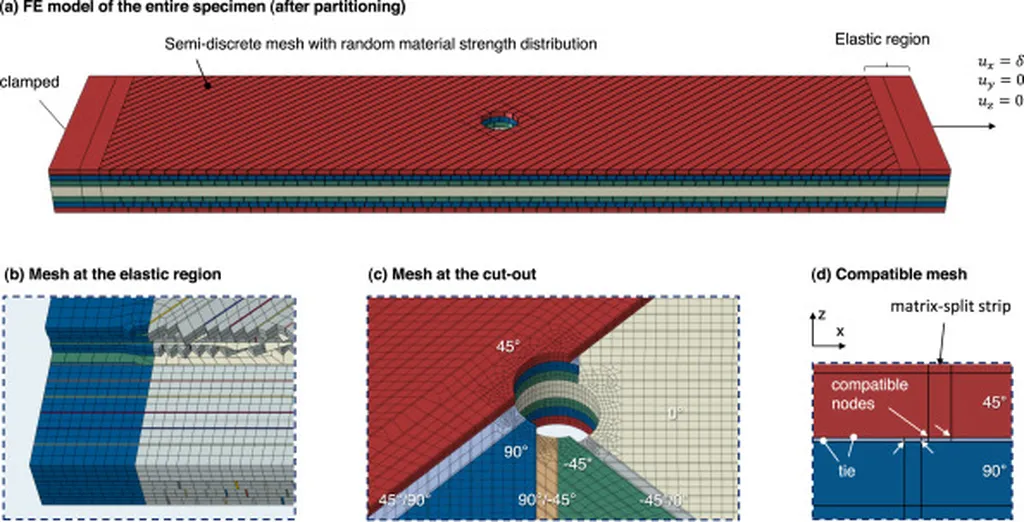

Delamination, the separation of layers in composite materials, is a critical issue that can compromise the integrity of structures ranging from aircraft wings to wind turbine blades. Traditional methods of modeling delamination using three-dimensional finite elements are notoriously computationally expensive, often requiring significant time and resources. Soman’s research introduces a novel approach that combines double-layer and single-layer shell elements, significantly reducing the computational load while maintaining accuracy. “Our method allows us to model through-the-thickness delamination effectively without requiring excessive computing time and memory,” Soman explains. This innovation could revolutionize how engineers approach the design and maintenance of composite structures, particularly in sectors where efficiency and reliability are paramount.

The implications for the energy sector are profound. Wind turbines, for instance, rely heavily on composite materials for their blades, which must withstand extreme environmental conditions and mechanical stresses. Delamination can lead to catastrophic failures, resulting in costly downtime and maintenance. By providing a more efficient and accurate modeling technique, Soman’s research could help engineers predict and prevent delamination, enhancing the durability and performance of wind turbines and other energy infrastructure.

Moreover, the study’s findings are not just theoretical. Soman and his team have compared their computational results with experimental data, validating the effectiveness of their approach. This bridge between theory and practice is crucial for translating research into real-world applications. “The accuracy of our modeling approaches is comparable to experimental results, which gives us confidence in the reliability of our method,” Soman adds.

As the energy sector continues to evolve, the demand for advanced materials and innovative modeling techniques will only grow. Soman’s research represents a significant step forward in this arena, offering a tool that could shape the future of composite material design. By making the modeling process more efficient and accessible, engineers can focus on developing more robust and reliable structures, ultimately driving progress in the aerospace and energy industries.

In an era where precision and efficiency are key, Soman’s work stands out as a beacon of innovation, poised to influence the next generation of engineering practices. As the industry continues to grapple with the challenges of delamination, this research provides a promising path forward, one that could redefine the standards of composite material design and application.