In the quest to optimize mineral processing, a team of researchers led by Ireneusz Szczygieł from the Institute of Thermal Technology at the Silesian University of Technology in Gliwice, Poland, has taken a significant step forward. Their work, published in the journal ‘Computer Assisted Methods in Engineering and Science’ (translated as ‘Komputerowe Metody w Inżynierii i Naukach Przyrodniczych’), focuses on the numerical simulation of single-phase flow in flotation machines, a critical component in the energy and mining sectors.

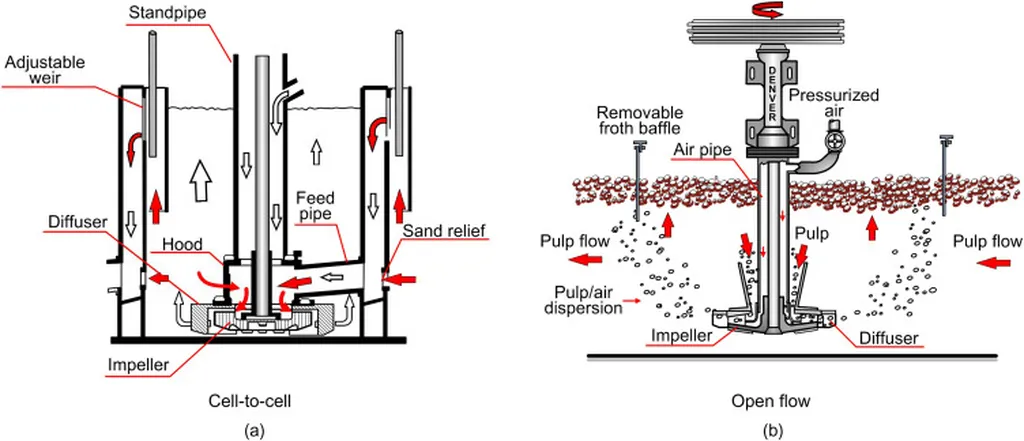

Flotation machines are integral to the processing of minerals, facilitating the separation of valuable minerals from gangue (worthless material) by taking advantage of differences in their hydrophobicity. The efficiency of this process is heavily influenced by the fluid flow within the machine. However, the complex phenomena involved—such as rotation, two-phase flow, and foam formation—have made comprehensive numerical modeling a formidable challenge.

Szczygieł and his team have tackled this complexity by focusing on the single-phase flow of water, a crucial aspect of the flotation process. “The efficiency of the flotation process strongly depends on the fluid flow field in the machine,” Szczygieł explains. “The level of mixing the fractions and air bubbles strongly depends on the velocity field of the water, so the proper model of fluid flow is of great practical importance.”

Using the commercial package ANSYS Fluent, the researchers conducted numerical simulations and compared their results with measurements performed on a small-scale model of the machine. The findings were encouraging, demonstrating the potential for further development of a complete numerical model of the flotation machine.

The implications of this research are significant for the energy and mining sectors. A comprehensive numerical model could revolutionize the design and modernization of flotation machines, leading to more efficient mineral processing and reduced operational costs. “Such a model would be very helpful in the process of construction and modernization of the flotation machine,” Szczygieł notes.

The research highlights the importance of numerical analysis and computational fluid dynamics (CFD) in advancing industrial processes. By understanding and optimizing the flow dynamics within flotation machines, engineers can enhance the efficiency and effectiveness of mineral separation, ultimately contributing to the sustainability and profitability of the energy sector.

As the team continues to refine their model, the potential for innovation in the field of mineral processing grows. This work not only sheds light on the complex phenomena involved in flotation but also paves the way for future advancements in the design and operation of these critical machines.