In a groundbreaking development poised to reshape the energy sector, researchers have introduced a novel approach to monitoring horizontal smart wells that could eliminate the need for costly downhole sensors. Published in *Scientific Reports* (known in English as *Nature Scientific Reports*), this study, led by Aiman Al-alimi of the Department of Petroleum and Geoengineering at Amir Kabir University of Technology, offers a game-changing solution to one of the industry’s longstanding challenges: the high cost and complexity of downhole instrumentation.

For decades, intelligent wells have been a cornerstone of reservoir management, enabling real-time optimization through downhole sensors. However, these sensors come with significant drawbacks—high costs, complex maintenance, and reliability issues. Al-alimi and his team have developed a surface-sensor-based methodology that predicts critical downhole parameters, including permeability, pressure, temperature, phase flow rates, and water holdup, without the need for downhole instrumentation. This innovation could revolutionize how the energy sector approaches well monitoring, offering a more cost-effective and operationally robust alternative.

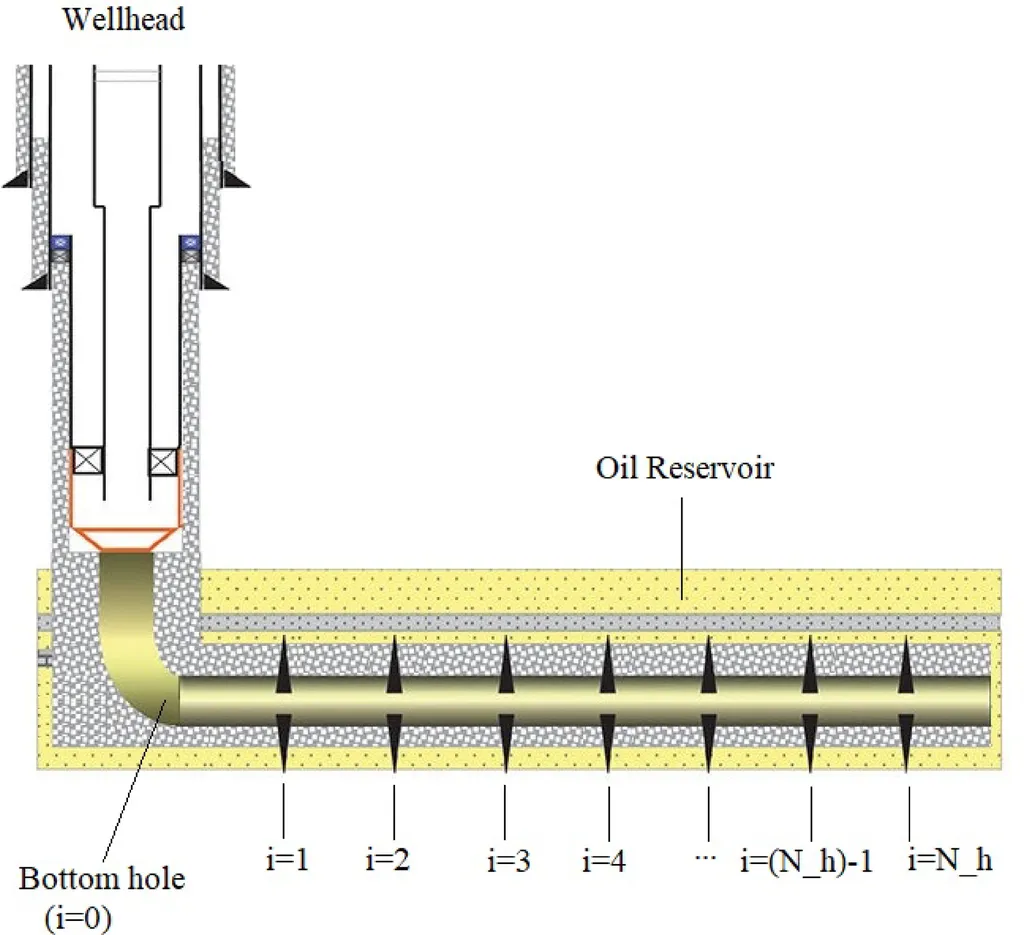

The research introduces two integrated models: Model I, which was validated against the industry-standard PUNQ-S3 reservoir simulation, and the Horizontal Well Simulation Model, which extends the methodology to practical field applications. The results are impressive. Model I achieved strong predictive accuracy with average relative errors of just 2.42% for water flow rates, 2.34% for oil flow rates, and 2% for pressure. The Horizontal Well Simulation Model further refined these predictions, yielding errors below 0.4% for permeability, pressure, water holdup, and temperature, and under 0.6% for flow rates.

This level of accuracy was achieved by integrating multiphase flow correlations—Duns & Ross for vertical sections and Beggs-Brill for horizontal sections—with Ensemble Kalman Filter-based data assimilation. This combination ensures reliable real-time predictions even under heterogeneous reservoir conditions. “Our approach not only reduces hardware and intervention costs but also enables proactive production strategies, mitigates water breakthrough risks, and extends well life,” Al-alimi explained. “This is a significant step forward in making smart well technologies more accessible and efficient.”

The commercial implications of this research are profound. By eliminating the need for downhole sensors, energy companies could see substantial cost savings, reduced maintenance downtime, and improved operational efficiency. This could lead to more sustainable hydrocarbon recovery, as well as safer and more efficient production processes. The study’s findings pave the way for a new era of surface-driven downhole prediction, setting a quantitative, field-ready framework for next-generation smart well technologies.

As the energy sector continues to evolve, innovations like this one will be crucial in meeting the demands for safer, more efficient, and sustainable operations. Al-alimi’s research not only addresses current challenges but also opens the door to future advancements in reservoir management. The energy industry is on the cusp of a transformation, and this study is a testament to the power of innovation in driving progress.