In the high-stakes world of high-power electronics, where reliability is paramount, a novel approach to mitigating void formation in solder joints has emerged, promising to enhance both thermal dissipation and mechanical integrity. This breakthrough comes from the lab of Jin-Kwan Lee at the Department of Advanced Materials and Process Engineering, Inha Manufacturing Innovation School in Incheon, South Korea, and it’s published in the journal *Results in Materials* (translated from Korean as “Materials Research Results”).

Void formation in solder joints has long been a thorn in the side of the electronics industry, particularly in high-power applications where heat management is critical. These tiny voids can significantly degrade thermal performance and mechanical strength, leading to premature failure of components. Lee and his team have turned to a unique solution: lotus-type porous copper (Lotus Cu), a material characterized by its uni-directional pores.

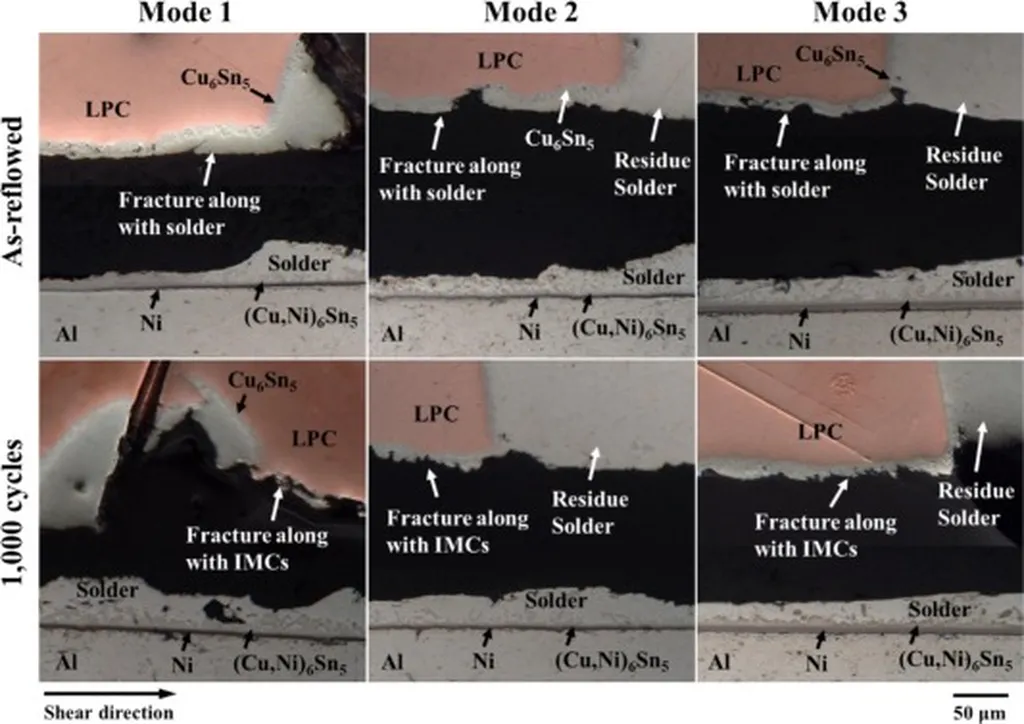

The team infiltrated the pores of Lotus Cu with SAC305 solder paste and performed reflow soldering under three different atmospheric conditions: air, nitrogen, and vacuum. The results were promising. “The shear strength of the Lotus Cu joint was slightly higher than that of the non-porous Cu joint,” Lee explained. Moreover, the void fraction in the Lotus Cu joints was lower than that in the non-porous Cu joints, indicating a significant reduction in void formation.

The implications for the energy sector are substantial. High-power electronics are the backbone of many energy systems, from renewable energy infrastructure to electric vehicles. Improving the reliability of these components can enhance the overall efficiency and longevity of energy systems, reducing downtime and maintenance costs.

“This research opens up new possibilities for designing more robust and reliable solder joints,” Lee said. “By leveraging the unique properties of Lotus Cu, we can potentially address some of the long-standing challenges in high-power electronics.”

The study not only sheds light on the potential of Lotus Cu but also underscores the importance of innovative materials science in driving technological advancements. As the demand for high-power electronics continues to grow, so too will the need for reliable and efficient soldering solutions. This research could shape future developments in the field, paving the way for more resilient and high-performance electronic components.

In an industry where every degree of temperature and every micron of material matters, this breakthrough offers a glimmer of hope for a more reliable and efficient future. As the research is published in *Results in Materials*, it invites further exploration and collaboration, setting the stage for the next wave of innovation in materials science and engineering.