In a groundbreaking development poised to reshape the landscape of soft robotics and underwater sensing technologies, researchers from the State Key Laboratory of Flexible Electronics (LOFE) & Institute of Flexible Electronics (IFE) at Northwestern Polytechnical University have introduced a novel 3D printable dual-sensing hydrogel system. This innovation, detailed in a recent study published in the *International Journal of Extreme Manufacturing* (translated as “International Journal of Extreme Manufacturing”), addresses critical challenges in the field of sensory hydrogels, offering a promising solution for applications ranging from underwater robotics to energy sector monitoring.

The research, led by Weizi Gao, focuses on the creation of an anti-swelling dual-sensing hydrogel system designed for digital light processing (DLP) 3D printing technology. This system is composed of a copolymer of N-acryloylsemicarbazide and acrylic acid, combined with the piezoelectric filler poly(vinylidene fluoride-trifluoroethylene). The hydrogel’s unique composition and structure inhibit swelling behavior in water, a common issue that has plagued previous iterations of sensory hydrogels.

“Our hydrogel exhibits exceptional mechanical properties, including high toughness, high strain levels, and high ultimate stress,” explains Gao. “This makes it particularly suitable for applications in harsh underwater environments where structural integrity and sensing capabilities are paramount.”

The hydrogel’s anti-swelling properties are achieved through abundant physical cross-linking and the formation of hydrophobic structures during the solvent exchange process. This results in an equilibrium swelling ratio of just 1.9% in water over 100 days, a significant improvement over existing technologies. Additionally, the incorporation of calcium ions enhances the hydrogel’s ionic conductivity, while the piezoelectric fillers endow it with dual-sensing properties, enabling it to detect both mechanical and electrical signals.

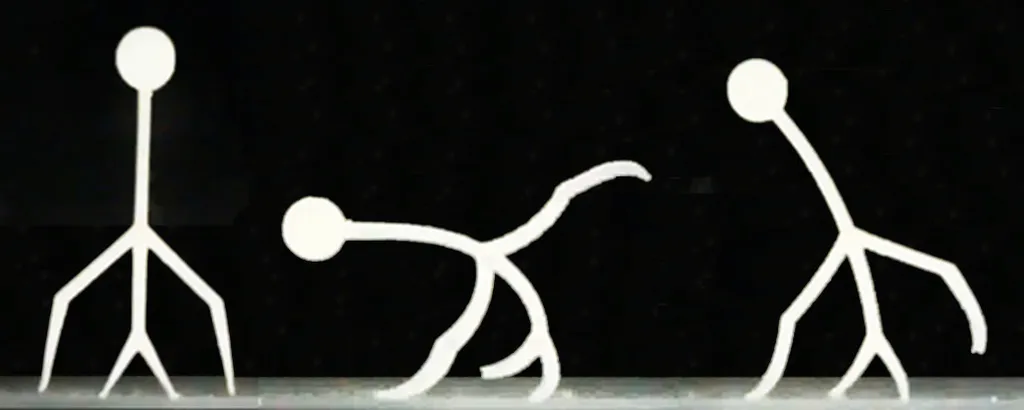

One of the most compelling aspects of this research is its potential impact on the energy sector. Underwater soft grippers based on this anti-swelling dual-sensing hydrogel could revolutionize the inspection and maintenance of offshore energy infrastructure. These grippers could be used to monitor the condition of underwater equipment, detect potential issues before they escalate, and perform precise manipulations in challenging environments.

“The ability to 3D print these hydrogels allows for personalized and customized structures, which is a game-changer for applications that require tailored solutions,” says Gao. “This technology opens up new possibilities for the development of advanced underwater robots and sensors that can operate in extreme conditions.”

The study also highlights the potential for visualizing underwater invisible motions, a capability that could enhance the safety and efficiency of underwater operations in the energy sector. By providing real-time data on the size and shape of objects, these hydrogels could guide further underwater work, reducing the risk of accidents and improving overall operational efficiency.

As the energy sector continues to explore and exploit underwater resources, the demand for robust and reliable sensing technologies will only grow. The development of this anti-swelling dual-sensing hydrogel system represents a significant step forward in meeting this demand, offering a versatile and durable solution for a wide range of applications.

In conclusion, the research led by Weizi Gao and his team at Northwestern Polytechnical University marks a significant advancement in the field of sensory hydrogels. By addressing key challenges related to structural instability and mechanical properties, this innovation paves the way for the development of next-generation underwater robots and sensors. As the energy sector continues to evolve, the potential applications of this technology are vast, promising to enhance the safety, efficiency, and reliability of underwater operations.