In a significant stride towards advancing orthopedic implant technology, researchers have developed a new class of titanium alloys with promising mechanical properties that closely mimic those of human bone. This breakthrough, published in the journal *Materials Research* (translated from Portuguese), could revolutionize the biomedical industry by offering improved implant compatibility and longevity.

The study, led by Nahuel Eduardo Spallanzani, focused on creating new Ti-xTa-xNb-xZr (x = 10, 20, and 30 wt.%) alloy systems. The goal was to identify metals with a low elastic modulus, a critical factor in reducing stress shielding—a common issue where implants are too rigid compared to bone, leading to bone resorption and implant failure.

Using advanced techniques such as X-ray diffraction, scanning electron microscopy, and energy-dispersive X-ray spectroscopy, the team characterized the chemical, structural, and microstructural properties of the new alloys. The results revealed that the addition of zirconium, tantalum, and niobium facilitated the formation of a body-centered cubic (β-BCC) crystalline phase.

“The formation of the β phase is crucial because it directly influences the mechanical properties of the alloy,” Spallanzani explained. “Our findings indicate that the Ti20Ta20Zr20Nb (TTZN20) alloy, in particular, exhibits an elastic modulus of 40 ± 5 GPa, which is remarkably close to that of human bone (about 30 GPa).”

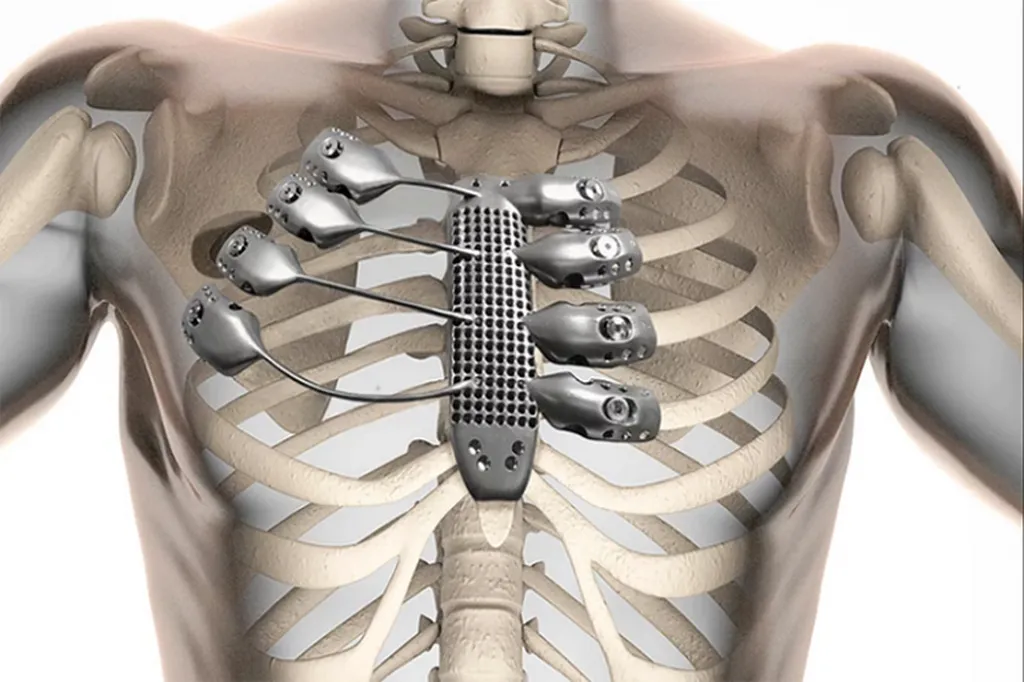

This close match in elastic modulus suggests that the TTZN20 alloy could significantly enhance the biocompatibility of orthopedic implants, reducing the risk of stress shielding and improving patient outcomes. The study’s implications extend beyond immediate medical applications, potentially influencing the broader materials science and engineering fields.

“The development of these alloys opens up new avenues for research and commercial applications,” Spallanzani noted. “By tailoring the composition and microstructure, we can design materials that are not only mechanically compatible but also biologically inert, reducing the risk of rejection and improving implant longevity.”

The commercial impact of this research is substantial. Orthopedic implants are a multi-billion-dollar industry, and the demand for materials that offer better performance and durability is growing. The TTZN20 alloy’s properties could lead to the development of next-generation implants that are more effective and longer-lasting, benefiting both patients and healthcare providers.

As the field of biomedical alloys continues to evolve, this research provides a foundation for future innovations. The ability to fine-tune the mechanical properties of titanium alloys could pave the way for customized implants tailored to individual patient needs, further advancing the field of personalized medicine.

In summary, the development of the Ti-xTa-xNb-xZr alloy systems represents a significant advancement in the quest for materials that closely mimic the properties of human bone. With its promising mechanical characteristics and potential for commercial applications, this research could shape the future of orthopedic implant technology and beyond.