In a groundbreaking study that bridges the gap between advanced manufacturing and artificial intelligence, researchers have developed a novel approach to predict the tensile strength of friction stir welded (FSW) AZ91D magnesium alloy joints. This development could revolutionize the production of lightweight, high-performance components crucial for the aerospace and automotive industries, with significant implications for the energy sector’s pursuit of efficiency and sustainability.

The study, led by K Rajesh Kumar from the Department of Mechanical Engineering at Vidya Jyothi Institute of Technology in Hyderabad, India, applied machine learning (ML) techniques to model tensile strength based on key process parameters. “Accurately predicting tensile strength is critical for producing reliable and high-performance components,” Kumar explained. The research, published in the journal “Materials Research Express” (translated to English as “Expressions of Material Research”), demonstrates the potential of ML models to optimize FSW parameters for AZ91D magnesium alloy, paving the way for more efficient and cost-effective manufacturing processes.

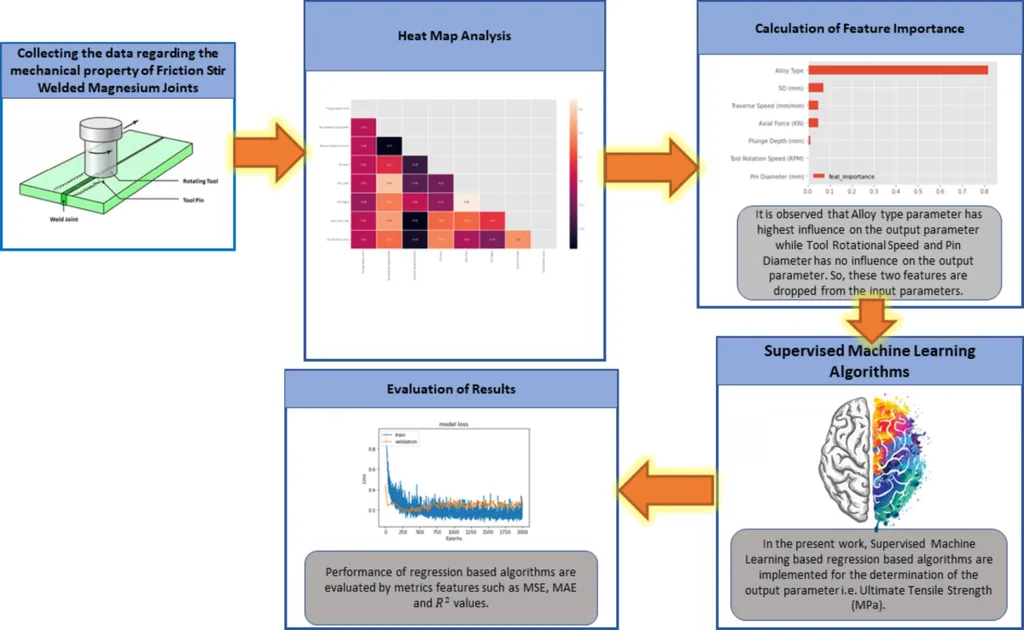

The team evaluated three regression models—Elastic Net (ELNET), K-Nearest Neighbors (k-NN), and Polynomial Regression—to predict tensile strength based on rotational speed, welding speed, and tool tilt angle. The results were impressive, with Degree-2 Polynomial Regression achieving the highest predictive accuracy (R² = 0.99). “The Polynomial Regression model outperformed the others, particularly in handling the nonlinear complexity of the data,” Kumar noted.

The optimal tensile strength of approximately 178 MPa was achieved at specific parameters: 710 revolutions per minute (rpm), 25 mm per minute welding speed, and a 3-degree tilt angle. Scanning electron microscopy (SEM) analysis revealed ductile fracture with dimples averaging around 12 micrometers in diameter and significant grain refinement at the weld interface due to dynamic recrystallization.

This research not only highlights the effectiveness of ML models in predicting and optimizing FSW parameters but also underscores the need for further validation on industrial-scale applications and other alloy systems. The implications for the energy sector are profound, as lightweight and high-strength materials are essential for improving the efficiency of vehicles and aircraft, reducing fuel consumption, and lowering emissions.

As the world continues to seek innovative solutions to pressing energy challenges, this study offers a promising avenue for advancing manufacturing technologies. By leveraging the power of machine learning, engineers and researchers can optimize material properties and processes, ultimately contributing to a more sustainable and efficient future.

The findings of this research open new possibilities for the application of machine learning in materials science and engineering. As Kumar and his team continue to explore these advancements, the potential for further breakthroughs in the field remains vast. The integration of AI and advanced manufacturing techniques holds the key to unlocking new levels of performance and efficiency, shaping the future of the energy sector and beyond.