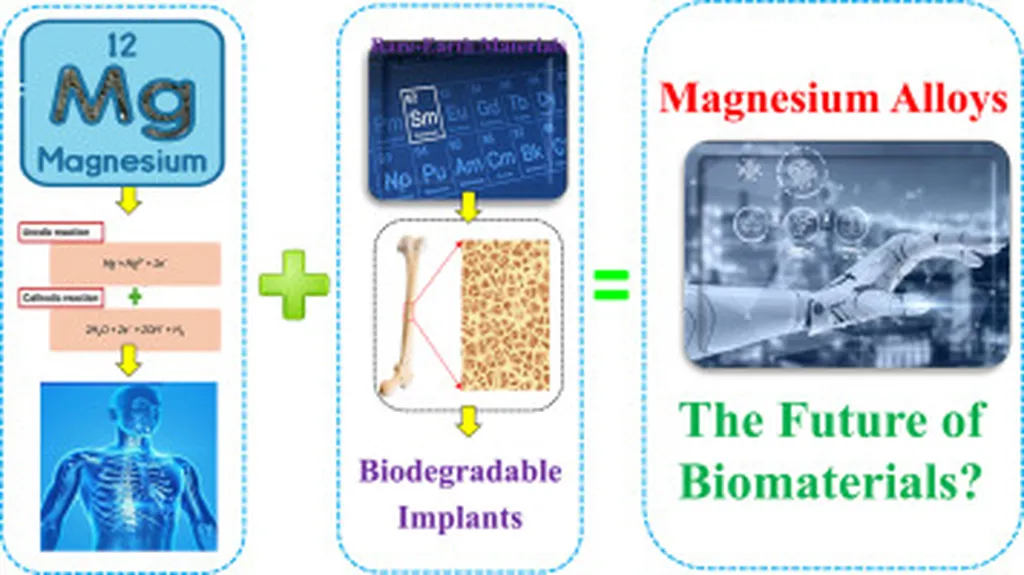

In the quest to develop better biomaterials for medical implants, researchers are turning to rare earth elements to enhance the performance of magnesium alloys. A recent study published in *Materials Research Express* (translated from Turkish as “Materials Research Express”) has shed light on the potential of neodymium (Nd) and lanthanum (La) in improving the tribological properties of ZK60 magnesium alloys in simulated body fluid environments. The lead author, Bilgehan Kondul Ugur from Karabuk University Faculty of Engineering and Natural Sciences, Department of Mechanical Engineering, has uncovered significant insights that could shape the future of biomaterial development.

The study focused on the addition of 0.5% Nd and La to the ZK60 magnesium alloy, comparing it with commercially available AZ31. The researchers conducted a series of wear tests in a simulated body fluid environment at body temperature, applying different loads and measuring the resulting wear and friction coefficients. The findings revealed that the ZK60+La alloy exhibited the highest average hardness at 73.05 HV, while the AZ31 sample had the lowest at 50.36 HV. Notably, the ZK60+La alloy also showed superior wear resistance compared to the ZK60+Nd alloy.

“Our results indicate that the addition of lanthanum significantly enhances the hardness and wear resistance of the ZK60 alloy,” said Bilgehan Kondul Ugur. “This could have profound implications for the development of biomaterials that are not only durable but also biocompatible.”

The study also highlighted the formation of secondary main phases such as MgO, MgZn, La₂O₃, and Nd₃Zn₁₁ with the addition of Nd and La, as detected by XRD. The highest average volume loss was observed in the ZK60+Nd sample, while the AZ31 sample exhibited the lowest average volume loss. Statistical analysis using ANOVA revealed that the material factor had a substantial impact on both the friction coefficient (56.85%) and volume loss (87.1%), with the load factor also playing a significant role.

The commercial implications of this research are substantial, particularly in the healthcare sector. As the demand for medical implants grows, the need for biomaterials that can withstand the harsh conditions of the human body becomes increasingly critical. The findings of this study suggest that the addition of rare earth elements like Nd and La could pave the way for the development of more durable and biocompatible implants.

Moreover, the energy sector could also benefit from these advancements. The principles of wear resistance and friction reduction are not limited to biomaterials but can be applied to various industrial applications, including energy generation and transmission. As the world shifts towards renewable energy sources, the need for materials that can withstand extreme conditions and reduce energy loss becomes ever more pressing.

In conclusion, the research conducted by Bilgehan Kondul Ugur and his team at Karabuk University Faculty of Engineering and Natural Sciences represents a significant step forward in the field of biomaterials. The insights gained from this study could shape the future of medical implants and have far-reaching implications for the energy sector. As the quest for better materials continues, the addition of rare earth elements to magnesium alloys offers a promising avenue for exploration.

The study, titled “Investigation of tribological performance of ZK60 material alloyed with rare earth elements (Nd, La) in body fluid environment,” was published in *Materials Research Express*, providing a valuable contribution to the ongoing research in this field.