In the quest to enhance the performance and efficiency of materials used in the energy sector, researchers have been delving into the intricate behaviors of alloys under extreme conditions. A recent study led by Huan Liu from the School of Automotive and Transportation at Shenyang Ligong University in China has shed new light on predicting the hot deformation behavior of Zr-4 alloy sheets, a material widely used in nuclear reactors and other high-temperature applications.

The study, published in the journal “Materials Research Express” (which translates to “Materials Research Express” in English), employed a combination of experimental data and advanced modeling techniques to better understand and predict how Zr-4 alloy behaves under various temperatures and strain rates. This is crucial for optimizing the manufacturing processes and ensuring the reliability of components in the energy sector.

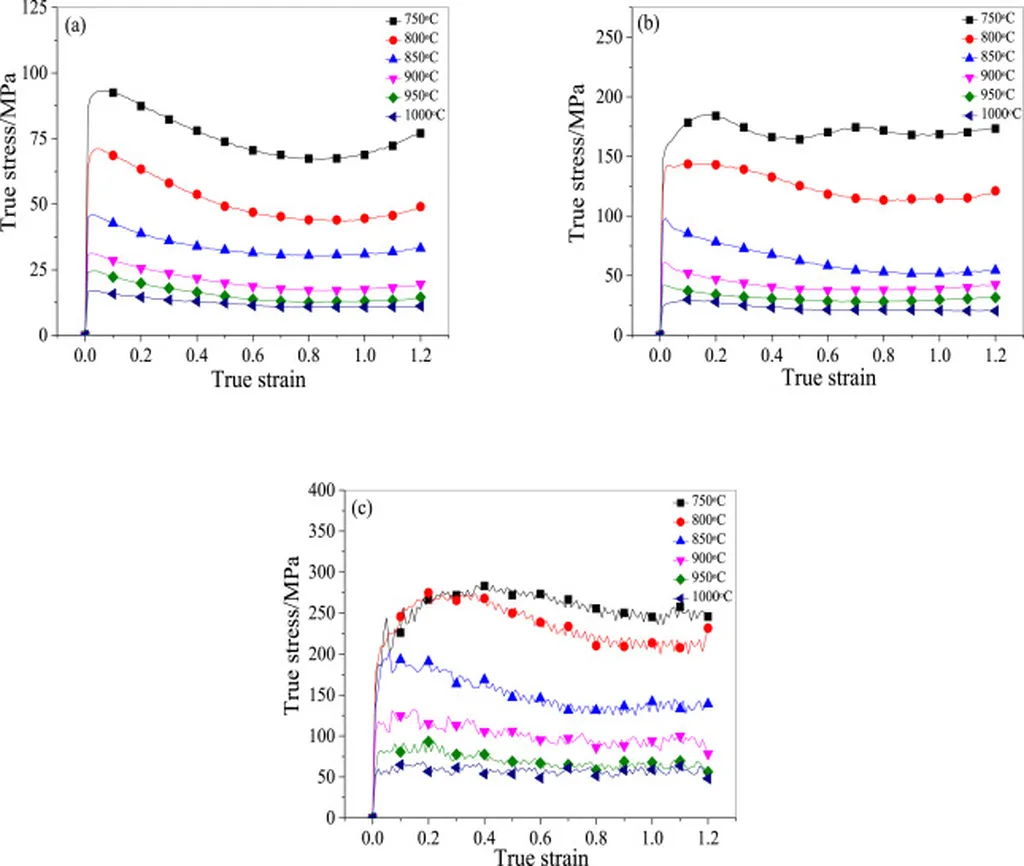

Liu and his team conducted hot compression experiments on Zr-4 alloy sheets using a Gleeble-3800 thermo-mechanical simulator. The experiments were carried out at temperatures ranging from 300°C to 800°C and at strain rates of 0.01 s^-1 to 10 s^-1. The goal was to gather data on the flow stress of the alloy under different conditions, which is a critical factor in determining its deformation behavior.

“We wanted to understand how the alloy behaves under extreme conditions to improve its performance and reliability,” said Liu. “This is particularly important for applications in the energy sector, where materials are often subjected to high temperatures and mechanical stresses.”

To predict the flow stress of the Zr-4 alloy, the researchers employed three different models: the strain-compensated Arrhenius model, a backpropagation neural network with the Levenberg–Marquardt algorithm (LM-BPNN), and a backpropagation neural network with the Bayesian regularization algorithm (BR-BPNN). Additionally, they enhanced the LM-BPNN model by integrating particle swarm optimization (PSO) and genetic algorithm (GA) techniques.

The results showed that the strain-compensated Arrhenius model and the LM-BPNN model had significant discrepancies compared to the experimental data. However, the prediction accuracy improved with the modified models using PSO-BPNN and GA-BPNN, although they did not capture all the features of the hot deformation curves. The BR-BPNN model, on the other hand, successfully captured all the features of the hot deformation curves, indicating the importance of selecting the right kernel functions for the BPNN model.

“This study provides a theoretical basis for researching the hot deformation behavior of Zr-4 sheets,” said Liu. “By understanding and predicting the behavior of this alloy under different conditions, we can optimize its performance and reliability, which is crucial for its applications in the energy sector.”

The findings of this research have significant implications for the energy sector, particularly in the design and manufacturing of components that operate under high-temperature conditions. By accurately predicting the deformation behavior of Zr-4 alloy, engineers can develop more efficient and reliable materials, leading to improved performance and safety in energy production.

As the energy sector continues to evolve, the demand for advanced materials that can withstand extreme conditions will only grow. This research represents a step forward in meeting that demand, providing valuable insights and tools for the development of next-generation materials.