In the realm of advanced materials, graphene oxide (GO) has long been a star player, but its synthesis methods have often been time-consuming and resource-intensive. A recent study published in the journal *Nanomaterials and Nanotechnology* (translated as *Nanomaterials and Nanotechnology*) by Andarge Ayele Adem from the Faculty of Material Science and Engineering has introduced a modified chemical oxidation method that could revolutionize the production of graphene derivatives. This breakthrough promises to significantly reduce both the time and resources required for GO synthesis, potentially unlocking new possibilities for the energy sector.

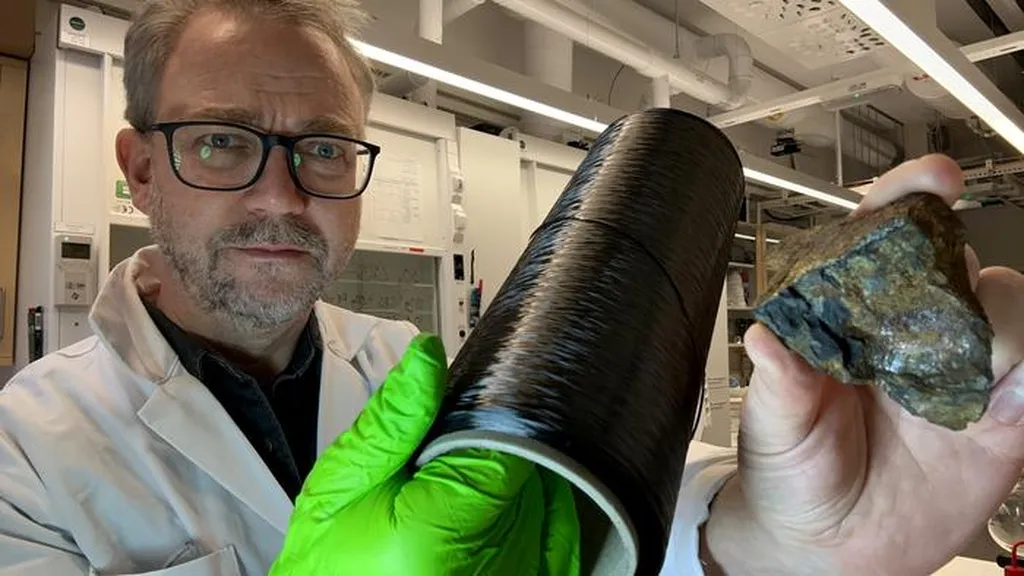

The study focuses on optimizing the Tour method, a well-known process for synthesizing graphene oxide. Adem and his team made a facile modification to this method, reducing the amount of acid intercalants and shortening the production time. The results are impressive: a 70% reduction in acid reagent usage and a 90% decrease in processing time compared to the traditional Tour method. Moreover, the modified method showed a significant improvement in process yield, ranging from 77% to 188% higher than the Tour method.

“The reduction in processing time and acid usage not only makes the synthesis more environmentally friendly but also opens up possibilities for large-scale production,” Adem explained. This is a crucial point, as the scalability of graphene oxide production has been a significant hurdle in its widespread application.

The synthesized GO samples were characterized using various techniques, including XRD, FTIR, and UV-Vis spectroscopy. The analysis revealed an interlayer spacing thickness of up to 0.82 nanometers, attributed to higher oxygenated functional groups between layers. The synthesized GO exhibited an estimated crystallite size of approximately 8 nanometers with an average number of layers of 10±1, a significant reduction compared to the precursor graphite.

The study also highlighted the impact of oxidation parameters such as processing temperature, time, and graphite inputs on the final product’s yield, oxidation level, crystallite size, and average number of layers. It was confirmed that processing temperature has a more pronounced effect compared to other parameters.

So, what does this mean for the energy sector? Graphene oxide has a wide range of potential applications, from energy storage devices like supercapacitors and batteries to advanced composites for renewable energy infrastructure. The ability to produce high-quality GO quickly and efficiently could accelerate the development and deployment of these technologies.

As Adem noted, “The potential applications of graphene oxide are vast, and this modified synthesis method could be a game-changer in making these applications more accessible and affordable.” This research not only advances our understanding of graphene oxide synthesis but also paves the way for future developments in the field, potentially shaping the future of energy technology.

In the ever-evolving landscape of materials science, this study stands as a testament to the power of innovation and its potential to drive progress in the energy sector. As we look to the future, the insights gained from this research could be instrumental in unlocking new possibilities and driving the next wave of technological advancements.