In the pursuit of optimizing metallurgical processes, a groundbreaking study led by Qiang Zhang from the School of Electronic Engineering at Yangzhou University in Jiangsu, China, has introduced a data-driven approach to predict coke strength after reaction (CSR) with remarkable accuracy. This research, published in *Energy Exploration & Exploitation* (which translates to *Energy Exploration and Exploitation*), promises to revolutionize the energy sector by enhancing the efficiency and cost-effectiveness of coking processes.

Coke strength after reaction is a pivotal parameter in metallurgical applications, influencing the quality and performance of steel production. Accurate prediction of CSR can lead to significant optimizations in coal blends and coking processes, ultimately reducing costs and improving product quality. Zhang and his team have developed a sophisticated machine-learning model that leverages eight key input variables, including moisture content, volatile matter, ash percentage, sulfur content, maximum fluidity, plastic layer thickness, mean maximum reflectance (MMR), and the basicity index.

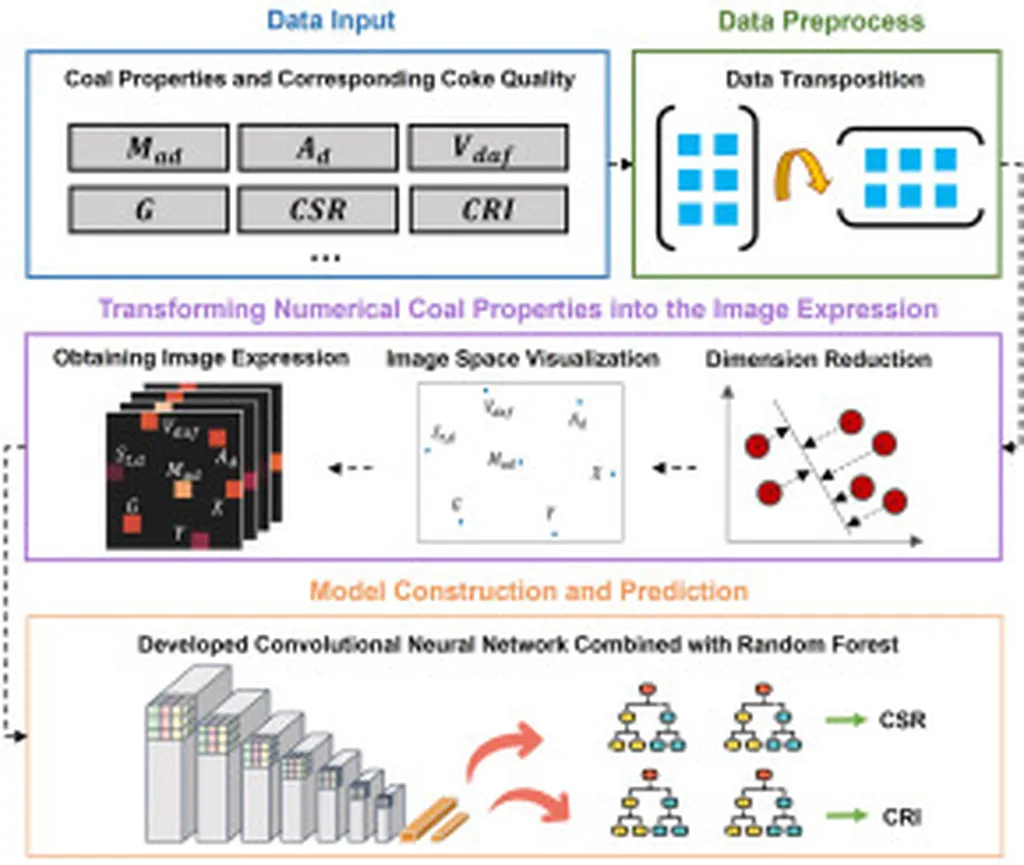

The study utilized a comprehensive dataset of 630 coal samples with diverse properties, employing advanced techniques such as Pearson correlation analysis and the Monte Carlo outlier detection technique to ensure data integrity. The team implemented various machine-learning algorithms, including random forests, decision trees, adaptive boosting, convolutional neural networks, support vector regression, and multilayer perceptron-artificial neural networks. Each model underwent rigorous evaluation using five-fold cross-validation and metrics like mean squared error, R², and mean and average absolute relative error.

The random forest model emerged as the clear winner, demonstrating superior predictive power with consistently high R² values and minimal error rates. “The random forest model decisively outperformed all other contenders, showcasing its robustness and reliability in predicting CSR,” Zhang noted. This finding underscores the potential of machine learning to enhance predictive accuracy in the energy sector.

Furthermore, the study employed Shapley additive explanations analysis to reveal the influence of each input variable on CSR. Volatile matter was found to have a predominantly negative effect on CSR, while features like MMR and moisture showed positive correlations. “Understanding the impact of each variable is crucial for optimizing coal blends and coking processes,” Zhang explained. “This systematic methodology not only improves predictive accuracy but also provides valuable insights for industry practitioners.”

The implications of this research are far-reaching. By enabling more accurate predictions of CSR, coke plants can optimize their operations, reduce waste, and enhance product quality. This, in turn, can lead to significant cost savings and improved competitiveness in the energy sector. “Our findings highlight the importance of robust data assessment and machine-learning models in driving innovation in the energy industry,” Zhang added.

As the energy sector continues to evolve, the integration of machine learning and data-driven approaches will play a pivotal role in shaping future developments. This research by Zhang and his team represents a significant step forward in this direction, offering a blueprint for enhancing predictive accuracy and optimizing metallurgical processes. With the publication of this study in *Energy Exploration & Exploitation*, the stage is set for broader adoption of these advanced techniques, paving the way for a more efficient and sustainable energy future.