In the quest for more durable and efficient engine components, researchers have made a significant stride by comparing the wear performance of two alloy steels, 42CrMo4 and 38MnVS6, commonly used in piston manufacturing. The study, led by JIANG Liyuan from the State Key Laboratory of Engine and Powertrain System, along with collaborators from Weichai Power Co., Ltd., Zhejiang University of Technology, Shanghai Jiao Tong University, and Shandong University of Aeronautic, sheds light on how these materials perform under varying loads and frequencies.

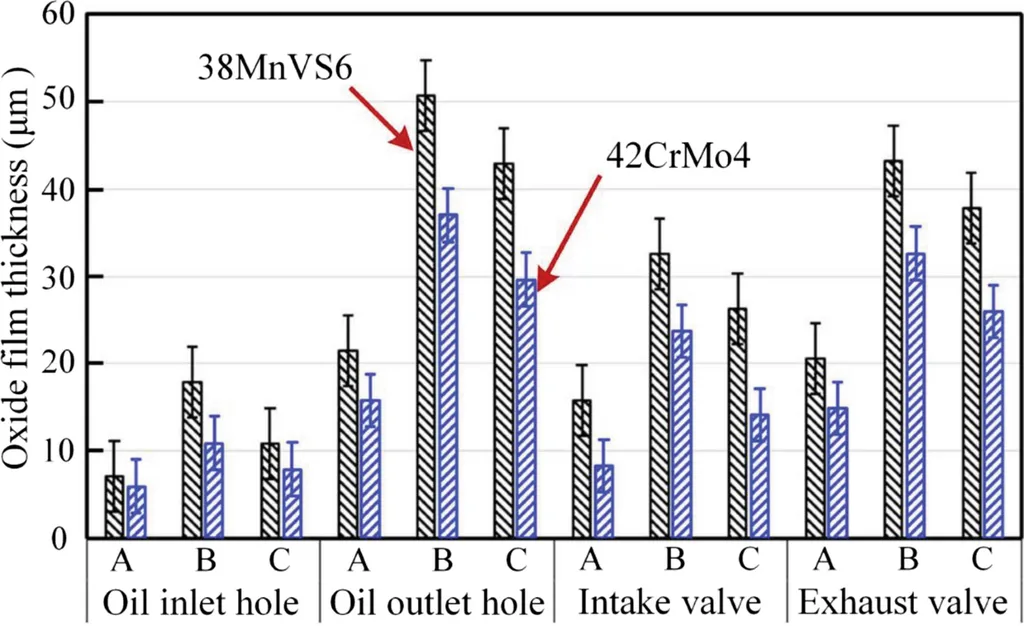

The research, published in *Cailiao Baohu* (which translates to *Materials Protection*), involved reciprocating dry friction tests on both alloy steels using GCr15 steel balls as counterparts. The team employed laser scanning confocal microscopy to analyze wear tracks and scanning electron microscopy (SEM) to examine worn surface morphologies. The findings revealed that 38MnVS6 outperformed 42CrMo4 in terms of wear resistance and friction reduction.

Under identical load conditions, the wear volume and wear rate of 38MnVS6 were reduced by up to 79.0% and 79.3%, respectively, compared to 42CrMo4. Similarly, under the same frequency conditions, the reductions were up to 72.9% and 70.3%. “These results indicate that 38MnVS6 exhibits superior friction-reducing and wear-resistant properties,” noted JIANG Liyuan, the lead author of the study.

The wear mechanisms for both steels were found to be a combination of adhesive wear and three-body wear, but 38MnVS6 showed a lower degree of wear. This makes it a more attractive option for piston manufacturing, where durability and efficiency are paramount.

The implications for the energy sector are substantial. Engines equipped with pistons made from 38MnVS6 could potentially offer longer lifespans and improved performance, leading to reduced maintenance costs and downtime. “This research could pave the way for more efficient and reliable engine designs,” added one of the co-authors, XU Jidong from Weichai Power Co., Ltd.

As the energy sector continues to evolve, the demand for materials that can withstand harsh operating conditions while maintaining high performance is growing. The findings from this study not only highlight the potential of 38MnVS6 but also underscore the importance of material science in driving technological advancements.

In the words of the researchers, “The superior wear resistance and friction properties of 38MnVS6 make it a promising candidate for various applications in the energy sector, particularly in piston manufacturing.” This research could shape future developments in material science and engineering, leading to more robust and efficient engine components.