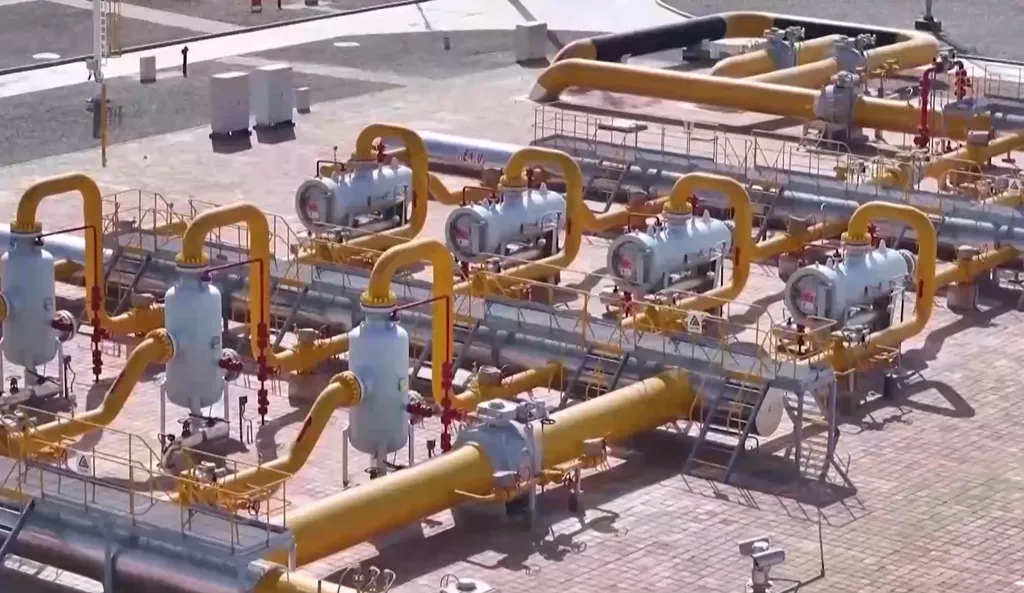

In the vast landscapes of Gansu and Xinjiang, where pipelines stretch across the terrain, a critical issue lurks beneath the surface—quite literally. Corrosion under insulation (CUI) is a silent menace that threatens the integrity of pipelines and equipment, posing significant safety risks and economic impacts. A recent study published in *Cailiao Baohu* (translated as *Materials Protection*) sheds light on this pressing issue, offering insights that could reshape how the energy sector approaches pipeline maintenance and safety.

Led by WANG Zhaozhang and a team of researchers from PipeChina Gansu Branch and the West Pipeline Company, the study delves into the high-temperature and low-temperature corrosion behavior of Q235 steel, a commonly used material in pipeline construction. The research focuses on the impact of different environmental media, including simulated soil solutions, polyurethane insulation layer leachate, and a mixed solution of both, on the corrosion rates of Q235 steel.

The findings are striking. At high temperatures, the corrosion rate of Q235 steel in polyurethane insulation layer leachate was significantly higher than in other environmental media. However, at a chilling 1°C, the mixed solution exhibited the highest corrosion rate. “The temperature during the production process and the environment in which the pipeline is located are significant factors affecting corrosion beneath the insulation layer,” explains WANG Zhaozhang, the lead author of the study.

The study employed weight loss tests and electrochemical testing methods at various temperatures to investigate the corrosion behavior. The results revealed that the absence of a salt crystal layer in the leachate environment, due to its low salinity, slowed the corrosion process. This led to further oxidation of the corrosion products, with Fe2+ corrosion products being further oxidized to Fe3+ products. Electrochemical impedance spectroscopy showed a reduction in impedance at the low-frequency region in the leachate, exhibiting diffusion characteristics.

The commercial implications of this research are profound. Understanding the corrosion behavior of Q235 steel in different environmental media can help energy companies develop more effective maintenance strategies, reduce downtime, and enhance safety. “By clarifying the corrosion patterns, we can better predict and mitigate the risks associated with CUI,” says WANG Zhaozhang.

The study, published in *Cailiao Baohu*, provides a crucial foundation for future research and practical applications in the energy sector. As the industry continues to evolve, the insights gained from this research could shape the development of new materials and technologies aimed at combating corrosion under insulation, ensuring the longevity and safety of critical infrastructure.

In an industry where every drop of efficiency counts, this research offers a beacon of hope, guiding the way toward a future where pipelines stand resilient against the ravages of time and environment.